How 3D printing is revolutionizing the old-timer industry and vehicle construction

If you have a classic car or just an older car you may know the trouble. Necessary spare parts are not available at all or have ridiculously long delivery times. The high prices of the part turn into the next big problem, that not only the end customer but also the manufacturer itself has to face. Producing parts in low volume, after serial production or parts that are highly specialized, is in many cases inefficient, especially due to the need of tooling and molds. And with the rising number of different models on the market the challenges grow steadily.

In our last webinar together with the German Association of Car Body Technology and Automotive Engineering (ZKF) we got to the bottom of the problem and showed how 3D printing could solve the challenge of missing spare parts and reduce costs of production for certain serial parts. Continue reading and we will guide you through our webinar.

3D printing can not only reduce costs but also improve customer service significantly

Our webinar started with a short introduction into the topic of 3D printing for body stores and classic car parts. Dierk Conrad, who is responsible for commercial vehicles and caravans at the ZKF is sure that 3D printing technology could revolutionize the repair of classic cars and the vehicle construction in general. But how?

Our technical sales expert, Amador Miano, explained: “With 3D printing parts can be produced more quickly and flexibly. Parts can be printed on-demand and without any necessary tools or molds. You just need the production files and a 3D printer that supports your part.” In this way production can start with lower ramp-up costs even in small lot sizes. In addition, printing can be decentralized, so there is no need to rely on traditional supply chains. And the part designs can be stored in a digital inventory, which enables eternal parts availability. This can not only reduce costs but also improve customer service significantly. Amador Miano showed the potential of 3D printing with some real live examples from the industry. Oldtimerparts, a startup from Leipzig, for example has rebuilt a window crank for a Opel of the 30s.

To optain a good result you must choose the right 3D printing technology

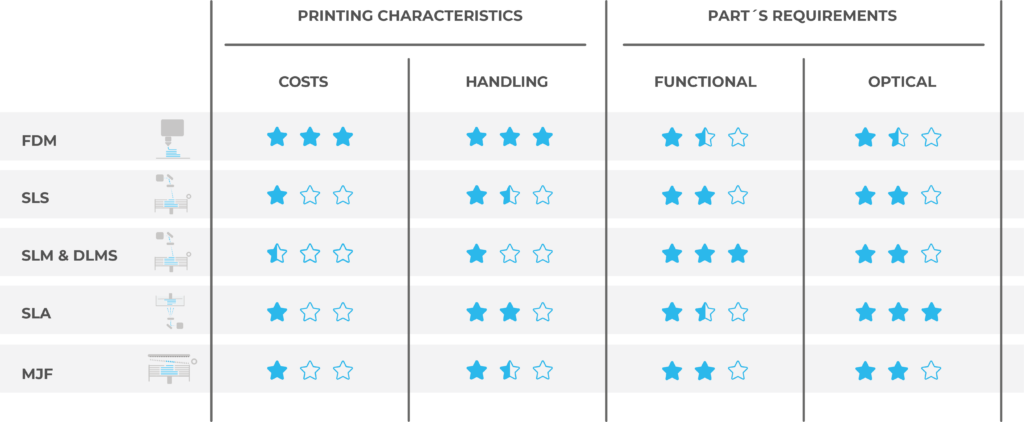

Of course, the right technology for the specific part has to be chosen. Amador Miano explained in the webinar, “However, 3D printing is just a collective term for different processes.” Choosing the appropriate technology depends on part requirements, for example, in terms of accuracy, strength, corrosion resistance, price and optical quality. In the table below you can see a short summary of the different technologies and its characteristics. If you want to learn more, you can also refer to our whitepaper where we explain you the differences between main 3D printing technologies.

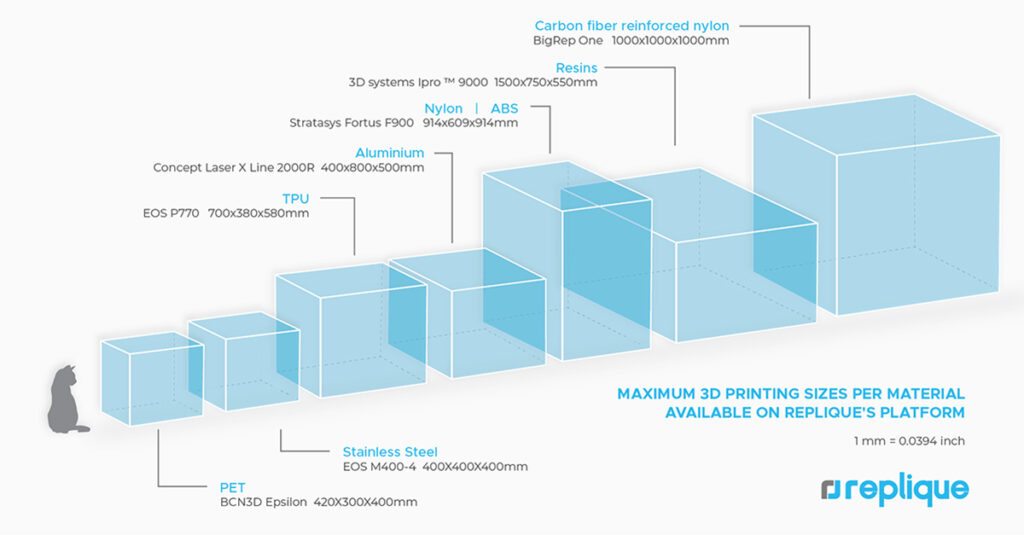

A question frequently raised by a lot of car manufacturers refers to the possible sizes of 3D printed parts. Amador answered this with a simple image that shows the print volume sizes of the mainly used materials and printer types within our production network.

The repair of highly valuable old-timers sometimes depends on a tiny little component

The possibilities for 3D printed classic car parts are endless. Imagine you have a Mercedes 540K, an old-timer worth 11 million euro and your bakelite switch for your dashboard broke. This switch is no longer available in stores. With 3D printing it can now be produced on demand, with costs ranging between 10 and 15 euros.

Another example: a metal heater lever for a Mercedes 300SL right now costs between 29 and 77 euros in stores. Using the 3D printing process, a similar plastic component can be produced for between 1.50 and 6 euros, depending on the quantity. With metal costs would range between 14 and 36 euros.

There are many other different use cases apart from spare parts, where 3D printing could be a cost and time saver. Sanel Zukic concluded the webinar with his own experiences with 3D printing at Carl Friederichs GmbH in Frankfurt am Main. In the company, 3D printing has already been in use for around four years. Among other things, the company manufactures special vehicles, for example for transporting prisoners or money. “3D printing is now indispensable as a process step in our workflows,” emphasized the design engineer. Components can be produced precision-fit and quickly. Some of the parts that they already print are armature board shelves with dimensionally accurate cutouts for the switches, an air duct for a prisoner transport system, and dummies for the installation of side windows.

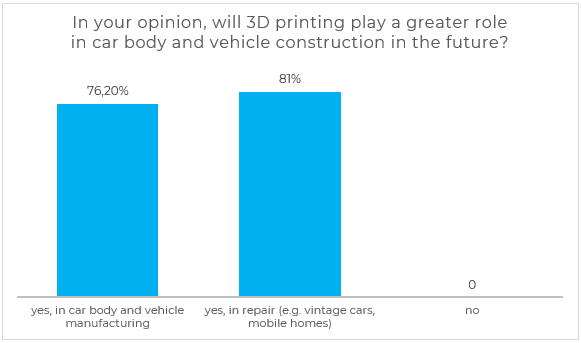

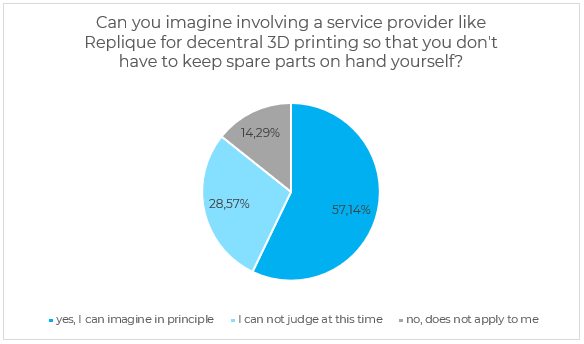

Webinar participants can imagine working with a 3D printing service provider such as Replique

The huge resonance to our webinar showed that the topic of 3D printing for components in the olassic car industry and vehicle construction in general is on the rise. This is also reflected in the survey conducted after the webinar. Around 80% of participants believe that 3D printing will have a mayor influence in car assembly and repair. With this technology, functional components, that are only available with great difficulty or not at all, can be produced cost efficiently. The fast and eternal availability of spare parts further increases customer service to a great extent. Within the survey it was clear, that a service like Replique can leverage those benefits furthermore with decentral production and digital storage of all parts.

You want to rethink vehicle construction and improve your aftermarket business? Contact us for more information at info@replique.io

Categories

- 3D printing industries (6)

- 3D Printing Materials (1)

- Basics (3)

- News (1)

- Point of View (10)

- Press (20)

- Press (20)

- Sustainability (3)

- Technology (6)

- Uncategorized (1)

- White Paper (1)