6 reasons why the packaging industry should shift to 3D printing

In today’s world, where a vast number of different products floods the market and customization plays a more important role than ever before, the packaging industry is facing a big challenge. Companies need to create tailored parts for machines used across various sectors. This not only leads to production complexity but also unnecessary costs due to high minimum order quantities and the need for storage of several different parts. Conventional manufacturing methods are hitting their limits.

This is where 3D printing comes into play. In the following sections, we will dive into the advantages of 3D printing for the packaging machinery industry and show how you can make use of the technology in the easiest and most efficient way.

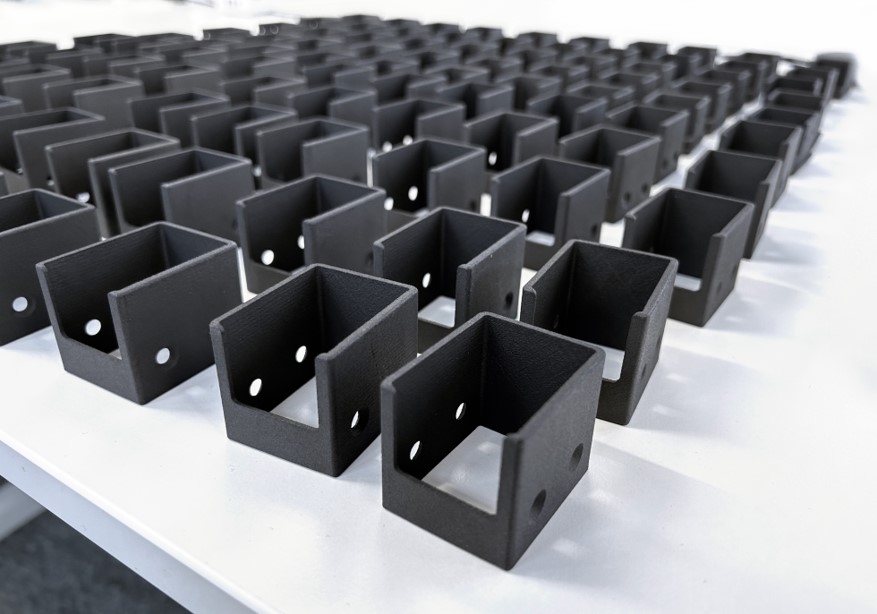

1. Customizing parts in small batches

In the packaging industry, each machine needs specialized parts, especially the ones that are directly in contact with the different products. Traditional ways of making these parts often require huge investments, as molds have to be created for rather low volumes. It’s like baking a single cupcake – you still need the whole oven, ingredients, and time, just for one treat. That’s where on-demand 3D printing comes in. With 3D printing you can just create the amount of parts needed with close to zero fixed costs.

2. Fast time-to-market and higher innovation capacity

This further enables producers to stay agile and responsive to changing market demands. Using 3D printing companies can quickly swift adaptation to new packaging formats with rapid prototyping. Creating a new design, testing, changing design until finalizing a part design to perfection becomes much quicker. The ability to swiftly design and produce tailored components enables packaging machinery manufacturers to bring new formats to market in record time.

3. One machine, multiple formats

Thanks to the quick availability of various 3D printed format parts, a packaging machinery could seamlessly transition between producing various formats with different variable quantities. This versatility not only enhances manufacturing efficiency but also offers a competitive advantage by allowing businesses to answer to different market demands swiftly and effectively.

4. Reduced downtimes with on-demand spare parts

If a machine in a factory suddenly stops working because a critical part broke, this can lead to huge downtimes. Producing a custom replacement part could range from 3 to 6 weeks, depending on factors like complexity and availability of resources. Even if the part is available in stock, the process of shipping it to the factory consumes valuable time, typically accounting for around 72 hours of transit. During this downtime, manufacturers not only bear the direct costs of stopped production but also face the opportunity cost of delayed shipments and potential customer dissatisfaction. The cumulative impact of these costs could easily exceed tens of thousands of dollars.

With on-demand 3D printing, that downtime could shrink to just a few hours. A qualified production file is all that’s needed, so a printer can produce the required part according to quality standards. If integrated into the business of the machine manufacturer, customers can simply order the part with the producer itself and get it produced via a 3D printing service bureau close to their location or even directly in their facility if they have the right 3D printer inhouse. This means less downtime, happier customers, and more money saved. By enabling quick part replacement, manufacturers can reduce downtimes by up to 90%.

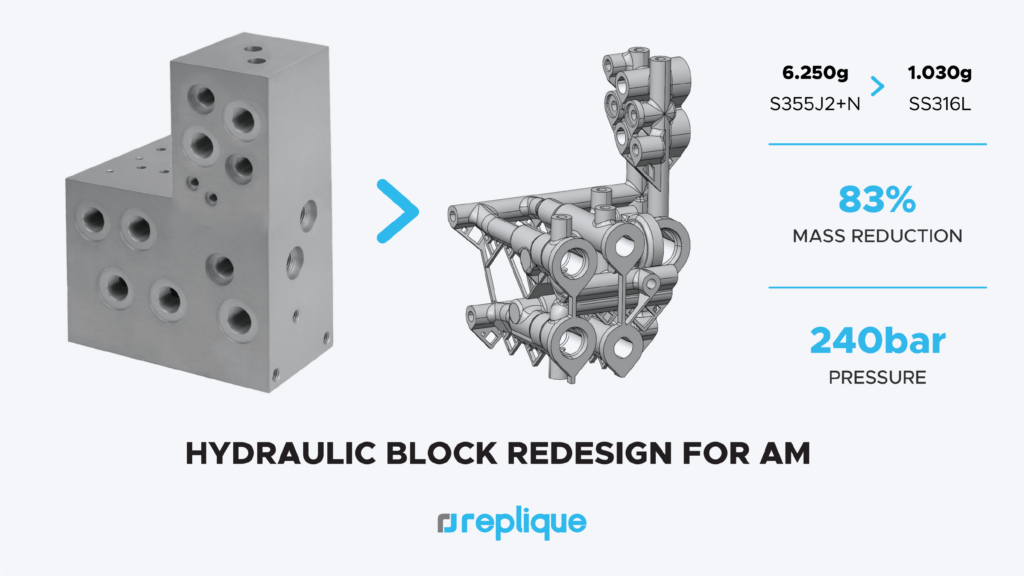

5. Design freedom

Unlike off-the-shelf solutions, 3D printing also enables manufacturers to integrate unique design of diverse packaging machinery parts. This allows designers to optimize the functionality and efficiency of their machines. Whether it’s adapting to unconventional shapes or accommodating specialized functions, customized parts empower designers to push the boundaries of innovation. For example the potential for part consolidation through on-demand 3D printing presents an avenue for streamlining the Bill of Materials (BOM), enhancing efficiency in design and assembly processes. The ability to create lightweight components with 3D printing moreover ensures that machinery maintains optimal performance while reducing unnecessary weight.

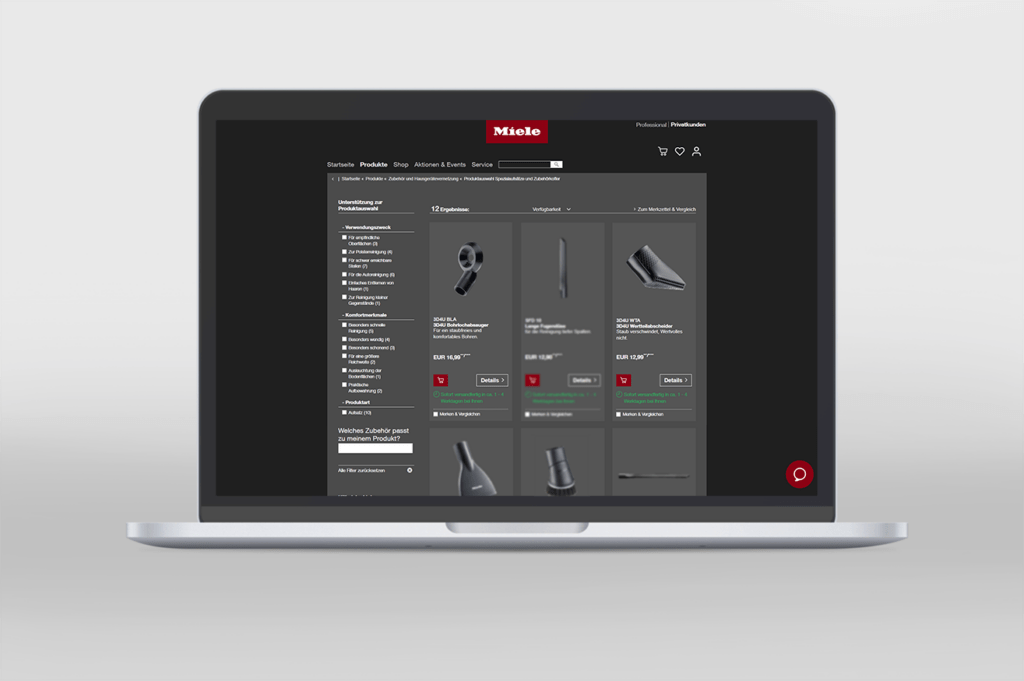

6. Digital storage of parts

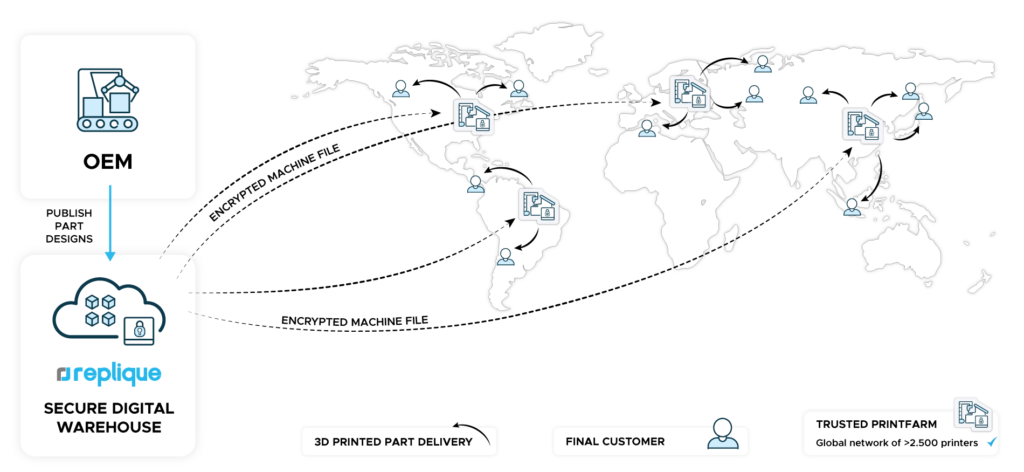

In addition to the tangible benefits of on-demand 3D printing, the digital storage of part designs and the concept of decentralized production further amplify its advantages. On-demand 3D printing isn’t just about making parts quickly. It’s also about being smart with space and resources. Instead of piling up tons of parts in a warehouse, companies can store the digital designs for those parts in a digital inventory such as on Replique which is connected to 3D printed service bureaus worldwide. Storing part designs digitally eliminates the need for extensive physical inventories, freeing up valuable warehouse space and reducing overhead costs. Moreover, by utilizing a decentralized production network which is connected to the platform, manufacturers can leverage a distributed ecosystem of 3D printers located near their facilities or even on-site, ensuring swift response times and minimizing shipping distances.

With Replique, an added layer of quality assurance emerges – the stored design involves pre-validated production parameters, ensuring that only accredited print jobs reach the 3D printing service bureau.

Access the whole 3D printing ecosystem with Replique

Replique enables seamless integration of 3D printing, where a great customer experience is highest priority. In just one platform, we combine all services from qualification to digital storage, on-demand production and post-processing. This includes all 3D printing technologies and materials on the market, so we can offer a solution for any part, without any knowhow required by our customer. And most importantly without any initial investment for inhouse technologies. Replique’s customers could simply order parts via the digital inventory for on-demand production. Or their end-customers could order parts directly from the machine manufacturer’s online shop, and this order zips through the digital inventory, all smoothly automated.

This approach isn’t just about saving costs – it’s about being eco-friendly too. It’s simple: make what’s needed, where it’s needed, and no extra stockpiles or outdated parts. Spare parts are ready to go whenever they’re needed, reducing waste and promoting repair. This approach improves the overall sustainability of machinery, keeping things efficient and forward-looking.

Want to reach higher flexibility and agility in your part production?

Request your quote via our secure upload page or just contact us directly!

Categories

- 3D printing industries (6)

- 3D Printing Materials (1)

- Basics (3)

- News (1)

- Point of View (10)

- Press (20)

- Press (20)

- Sustainability (3)

- Technology (6)

- Uncategorized (1)

- White Paper (1)