The added value of an additive manufacturing platform

Additive manufacturing is starting to find its place in the manufacturing environment. Either for prototyping, low to mid-size series or even series production, it offers big benefits like design flexibility, low investment costs and reduction of material waste. However, to really achieve having parts available anytime and anywhere, it is necessary to combine the technology with decentral manufacturing. Like this, you greatly reduce lead times, shipping costs and emissions and have access to several different locations and technologies. The easiest way to shift to decentral manufacturing is choosing an additive manufacturing platform. Why? We will show you the three main benefits in this blog post

.

Get access to all additive manufacturing technologies, materials and post processing options via one platform

Henry Ford, founder of the car manufacturer Ford, famously said during a meeting in 1909 that Ford can produce cars in any color as long as they’re black. Back then it was acceptable that there were no choices regarding colors or materials. Nowadays this is not the case anymore and the customer expects numerous product options regarding colors, materials etc.

Of course, customers have the same requirements to additive manufacturing, regarding a wide range of material, colors etc. And there are already numerous of different printing technologies, materials and post processing options. However, to offer all possible material–technology combinations and post processing options in–house is nearly impossible. Even offering all these options with an own network of production partners is extremely challenging. It will probably lead to the fact that you need to have dozens of partners.

This is something where a platform for additive manufacturing is very useful. The core business of such a platform is to offer all different technologies, materials and post processing options to its customers.

Replique, the industrial grade additive manufacturing platform, offers all frequently used printing technologies, materials and post processing options, as well as some more unique options. If there is a technology, material or post processing option that Replique does not have in their portfolio yet, they will search for a qualified partner and onboard them into their production network.

Get a free material sample set to get a look and feel of different 3D printing materials.

Produce worldwide with a global 3D printing network

With traditional manufacturing methods you produce parts centrally and ship them around the world. One of the reasons for this is that you can only use production machines in traditional manufacturing for a single or small range of different products. Moreover, you have to train employees for the specific machine and of course the machines take up space and investment.

With additive manufacturing it’s possible to produce a wide range of different products on one printer. This makes it possible to have printers located around the world and produce numerous parts close to the consumer. This possibility to produce locally is one of the big advantages of an additive manufacturing platform. It saves shipping time and costs, reduces the influence of supply chain disruptions, plus it is more environmental friendly.

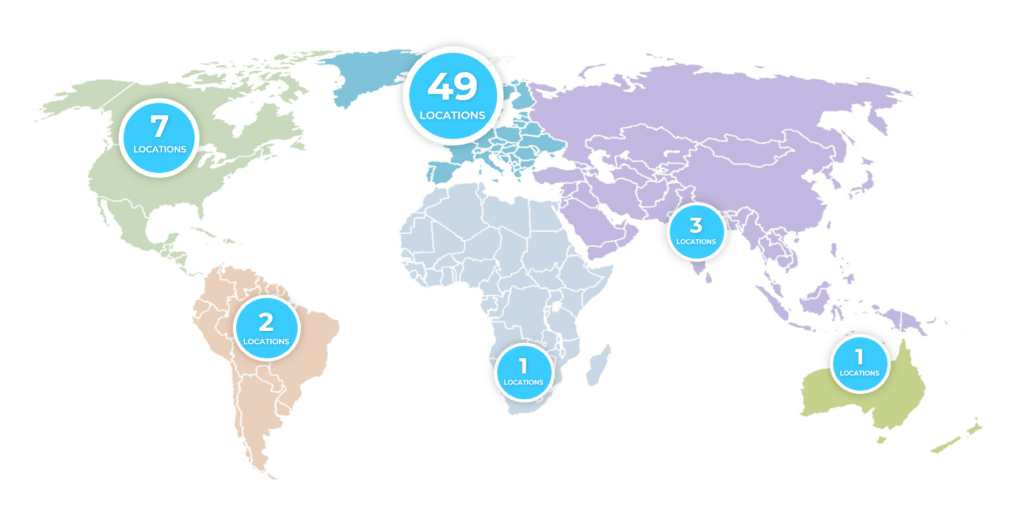

Replique has a global network of production partners and can support customers in six different continents. Currently Replique has over 60 certified production partners worldwide. In the image below you can see where these partners are located.

As the biggest customer base is located in Europe, of course most of Replique’s production partners are also located there. This way Replique can offer a high material-technology mix and produce the parts as close to the customer as possible. Besides Europe there are also multiple partners in north America, since this is also a growing market for Replique. Replique constantly expands the production network with new technologies/materials and to new areas depending on the needs of customers.

Quality assurance integrated into your additive manufacturing platform

When you produce parts externally and the print farm ships them directly to the end customer it’s hard to keep track of the quality. That is, because the parts are never in the hands of the Original Equipment Manufacturer (OEM). This can be one reason for an OEM to not go and produce external and decentral.

Replique has three ways to maintain the quality level that the OEM expects:

High quality service bureaus via platform

Replique only works together with service bureaus from which they are confident that they can reach a certain quality level. One of the ways how Replique finds service bureaus that can offer this quality level is by quality certifications. For instance, most of the service bureaus in Replique’s network are ISO9001 certified. ISO 9001 is a set of standards that help companies ensure to meet requested needs and requirements related to a product or service. Multiple of Replique’s customers actually demand that their parts are produced in an ISO 9001 certified production location.

While ISO9001 is a general quality management certificate there are also special certificates that focus on the needs in certain markets. Examples are for instance AS 9100 (Aerospace) and ISO 13485 (Medical). One third of the partners in Replique’s production network have such an industry specific quality certificate. This helps Replique to define which service bureau is the best fit for a certain customer request.

Before working with a service bureau, Replique checks the processes and production quality of each service bureau. Later on, Replique monitors the performance of a service bureau. Like this, low performing service bureaus risk of being removed out of the network.

Encryption of production files

Most service bureaus work in a way where they receive a 3D file, decide on the parameters and print the part. Replique works slightly different. Replique works with encrypted production files. They store ready-to-print files in the Replique platform where the parameters are already set. Due to this you can expect the same print quality of the products, no matter where or when they were printed. Besides that, this encryption also protects the intellectual property of the owner. The files are encrypted, and so cannot be changed or printed without consent.

Quality feature integrated in the 3D printing platform

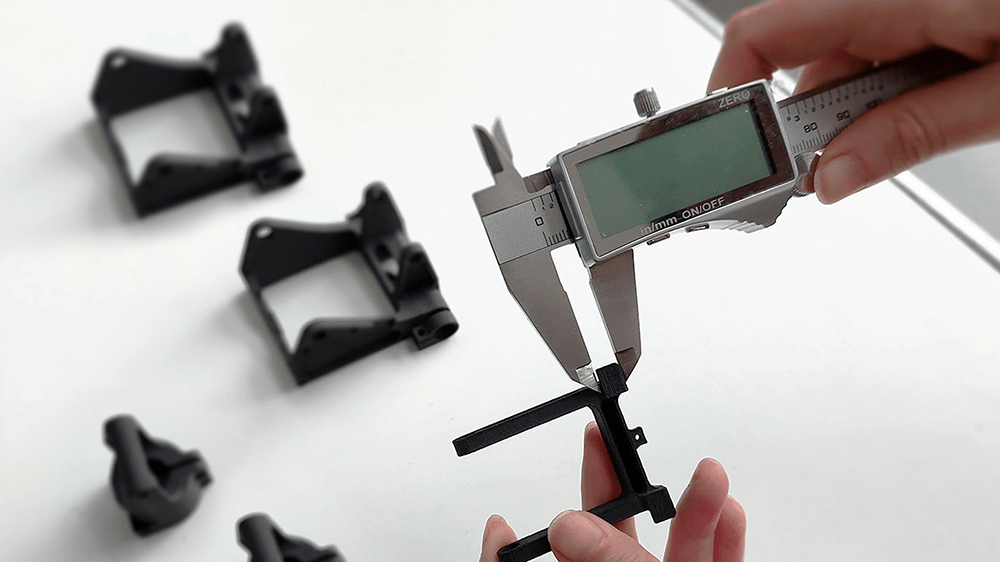

Replique’s platform offers a quality feature where customers can decide what kind of quality checks the print farm has to perform on the parts. This could for instance be that the print farm has to measure certain dimensions, take photos or execute a certain functional test. This is all documented in the platform, so that OEMs can see if the checks have been done and what the results are.

Learn more: How to ensure quality in 3D printing

Make the most out of additive manufacturing with an industrial 3D printing platform

An additive manufacturing platform enables you to leverage full potential of additive manufacturing. It offers the general benefits of additive manufacturing (e.g., design flexibility, low investment costs and reduction of material waste). On top of that it adds to that the benefits of producing decentral (lower lead times, costs and emissions).

Replique’s industrial additive manufacturing platform offers even a third dimension of benefits on top: The global coverage, the availability of all technologies, materials and post processing options, as well as quality assurance.

Do you want to leverage the full benefits of 3D printing. Contact us and we can help you scale your business!

Categories

- 3D printing industries (6)

- 3D Printing Materials (1)

- Basics (3)

- News (1)

- Point of View (10)

- Press (20)

- Press (20)

- Sustainability (3)

- Technology (6)

- Uncategorized (1)

- White Paper (1)