How to ensure quality in 3D printing

Quality is key when it comes to the production of parts, especially in series. Many sectors such as aerospace and automotive require the fulfilment of high standards and a consistent part quality.

With additive manufacturing being more and more used in industrial applications, quality assurance (QA) therefore becomes one of the most important topics.

How to define the quality of a 3D printing process

In injection molding for example, producers ensure repeatable quality thanks to the mold which makes sure that parts are produced the same way every time. In 3D printing however, producers cannot fully guarantee the quality of the part after production. The printing process of a part is a long process influenced by many printing parameters that interact with each other. This can be for example printing speed, amount of deposited material, filling structures, support structures, sintering time and layer height. Moreover, there are numerous external factors that affect the performance of the printer. Factors are for example the calibration, conservation of materials, maintenance, adhesives and printing surface, operators, and even air humidity and temperature.

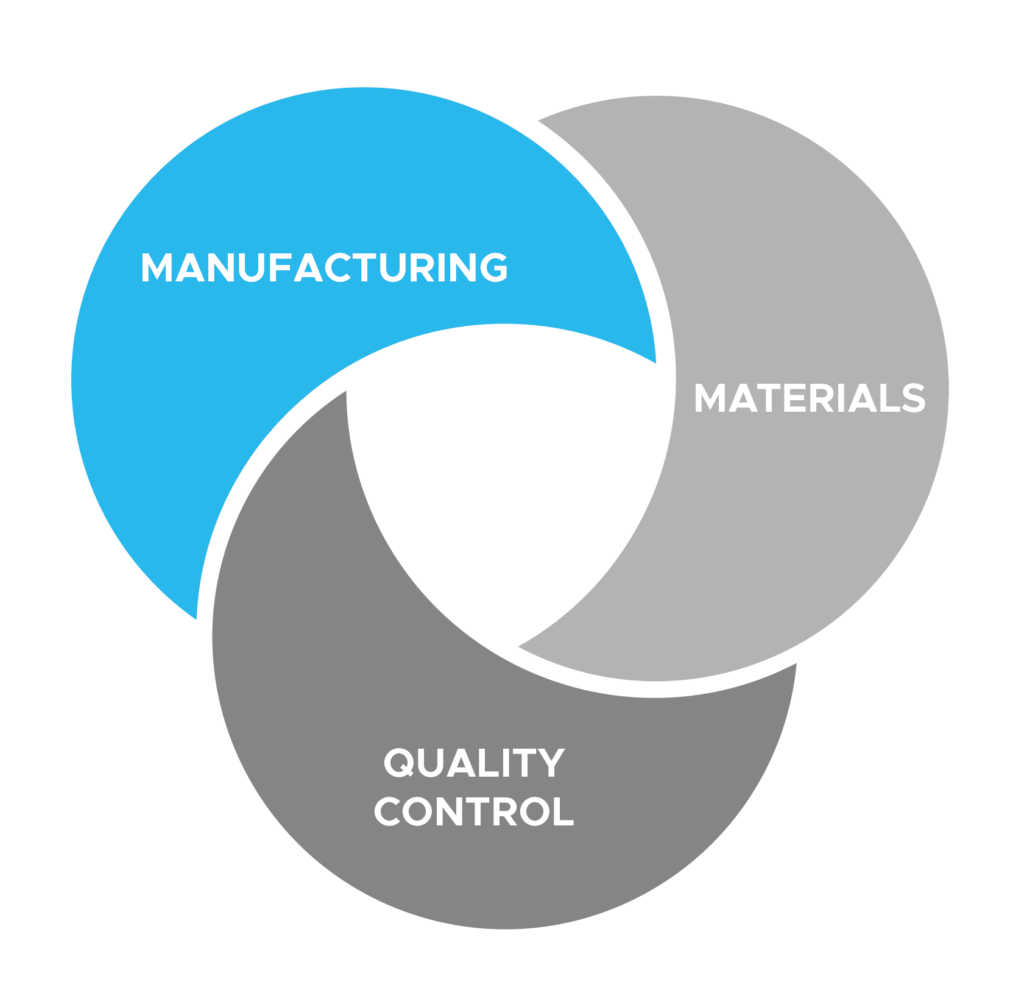

To allow a reliable manufacturing of 3D printed parts, the quality has to be repeatable and proven (under the same conditions: printer, materials, printing parameters, etc.). There are three main risks concerning the quality of the 3D printing process:

- The quality of the material resources and their conservation

- Quality of the manufacturing process of the parts

- Quality control

Materials as part of the quality parameters in additive manufacturing

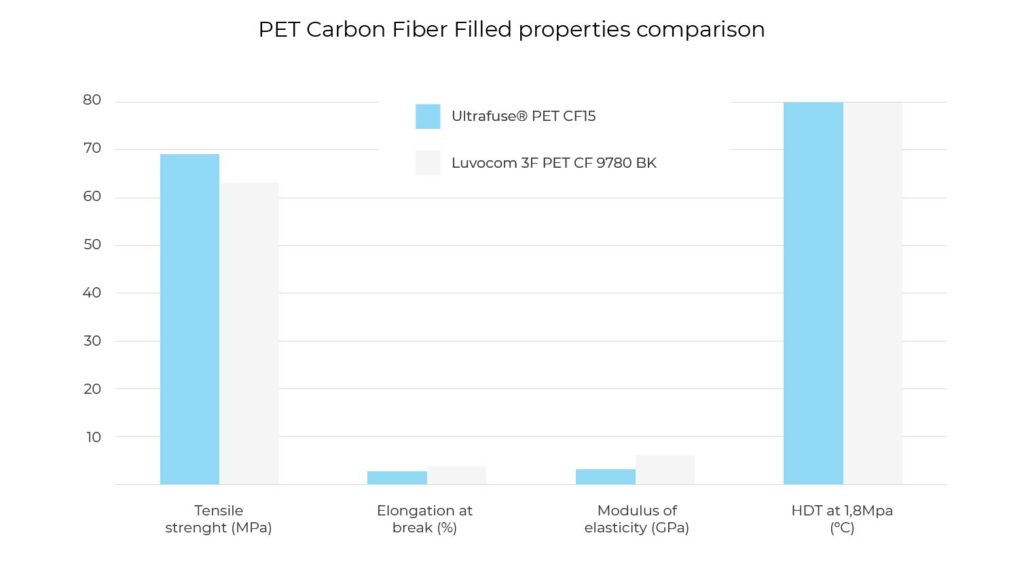

Each material manufacturer has different manufacturing formulas. Even if we are looking at the same 3D printing materials, each supplier adds their own additives and compounds. This leads to the fact that material properties may vary slightly from one material manufacturer to another.

In addition, the quality requirements may vary from one manufacturer to another. This could for example be different requirements for the control of filament diameter, size and homogeneity of powder particles or homogeneity of resins. Materials of unknown origin or quality pose a potential risk to the final performance of printed parts. This is of particular concern when companies use parts in critical equipment or quality-sensitive products such as medical devices and products in contact with food. That is why the selection of suitable materials is crucial.

Together with Forward AM for example, brand of BASF 3D Printing Solutions, we had to find a solution for a 3D printed accessory of Miele that is in contact with food – a coffee clip. We not only had to find a food-safe 3D printing process, but also adapt the whole production process and carry it out in accordance with Good Manufacturing Practice (GMP). This ensured that no external contaminants are introduced into the production process.

In addition to the production of the materials, the preservation of the materials plays an important role in maintaining 3D printed part quality. Materials can lose quality over time and if producers don’t store them in the right humidity, light or temperature conditions. For traceability, at Replique we document material batch numbers. In case of quality issues of a batch, Replique knows exactly which parts are printed with this batch.

Assuring high quality in the additive manufacturing process

To ensure that a manufacturing process produces quality parts is a painstaking task. As long as they are not very simple parts, it requires an analysis of the geometry, used materials and the development of qualified printing parameters. Depending on the design, different 3D printing technologies could be suitable or not.

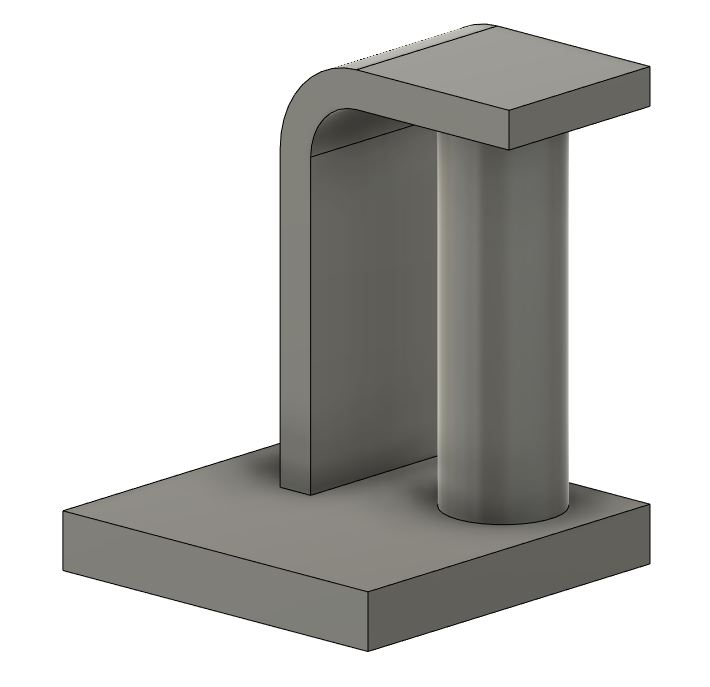

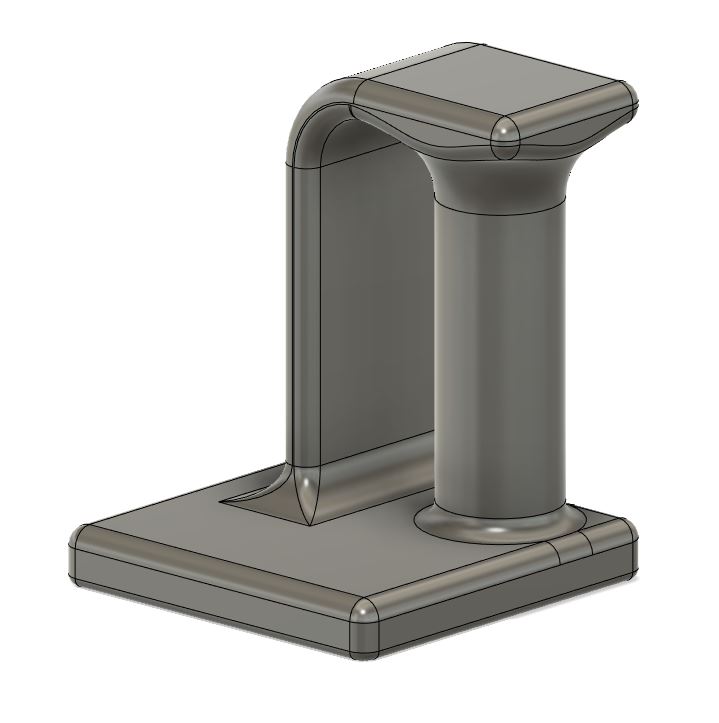

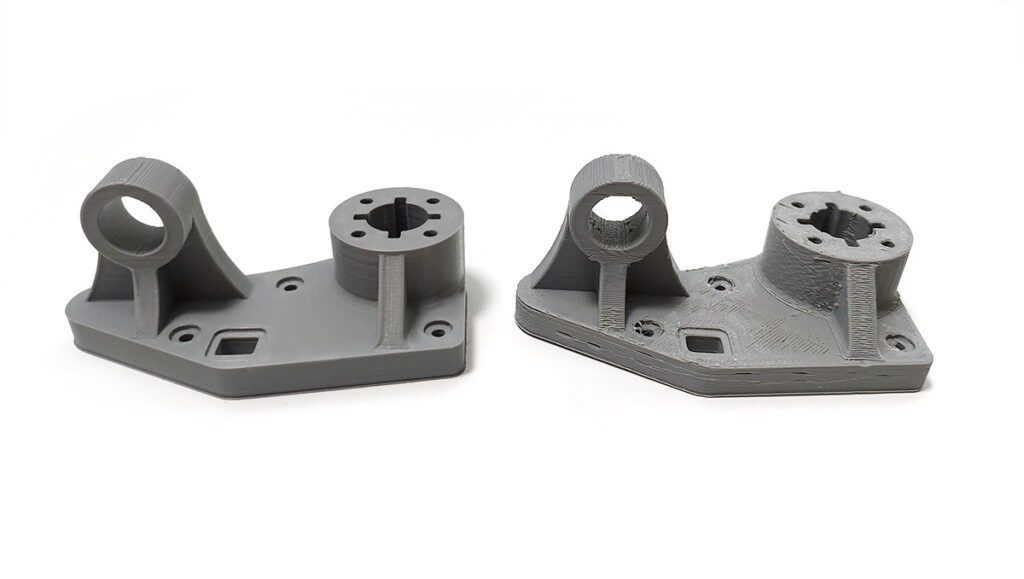

In 3D printing, you often cannot copy the geometry of the original part 1 to 1. And sometimes redesigning it could even lead to better part properties, less material used and therefore also less part weight. When designing for 3D printing there are a series of considerations you have to think of to allow a good part quality. This includes for example wall thickness, part orientation in the chamber, and avoiding sharp edges. If a part has not been successful in printing it could be successful by just slightly modifying its geometry.

Not every material used in traditional manufacturing also exists in 3D printing. And even if the material exists, its properties might vary slightly (impact resistance, properties depending on the orientation of the part when printed, …). A good knowledge of additive manufacturing techniques and available materials is necessary to find the best alternative to traditional production materials, which will result in a part with successful print quality. Here, also qualification plays a huge role. As soon as you change a material, process or design compared to the traditional and already approved process, you have to retest the part to assure its quality and safe use.

Often, material producers are not as advanced in additive manufacturing as for example 3D printing service bureaus. Therefore often 3D printing engineers within a 3D printing service bureau develop the right printing parameters for a material. Printing experience and previous work with the materials decide if they ultimately print the part with the right parameters and in high quality or not. And not only the material, but also the geometry of a part influences the printing parameters, which makes it even more complex.

You might wonder now, how the printout quality can become repeatable in different locations, if every manufacturer develops its own printing parameters. Repeatability is of course one of the main factors to ensure a qualified serial production. We at Replique have found a way to solve this problem, by enforcing the printing parameters on our platform. That means, if a producer within our network gets a customer order from us, they can only produce the parts with the before defined printing parameters.

Quality control is necessary to track each 3D printed part

Traditional manufacturing processes incorporate quality control ranging from manual inspection to destructive or non-destructive testing. These quality control processes are fully established in the industry. In 3D printing however, the produced parts on each printer are changing constantly and lot sizes are much smaller than in traditional manufacturing. That is why some producers of non-critical 3D printed parts that do not have high quality requirements lack strict quality control processes.

But additive manufacturing is no longer a developing technology. It has moved from being used mainly for prototypes or high value-added industries (aeronautics, aerospace, …) to a stage of maturity where it is establishing itself as a standard in all industrial sectors. This makes it important to start adopting the technology responsibly and with an eye on quality control.

Quality inspection is one important part to assure high quality. At Replique, we for instance focus on visual inspection, measurements of dimensions, weighing the parts and taking pictures. Us and our printing partners then correct possible failures by for instance changing printing parameters, used materials, post processing alternatives or even the geometry of the part.

For more critical parts, standards should be applied to ensure 3D printed part quality. A quality documentation plays an important role to keep track and ensure quality of all additively manufactured parts. To ensure traceability, we at Replique for example add an automated quality report linked to the spare part. Digital documentation of production processes reduces manual effort and saves the information about each part produced.

You need help in 3D printing your part in high quality? Just contact us and we can support you in analyzing your part and making your 3D printing journey a success.

Categories

- 3D printing industries (6)

- 3D Printing Materials (1)

- Basics (3)

- News (1)

- Point of View (10)

- Press (20)

- Press (20)

- Sustainability (3)

- Technology (6)

- Uncategorized (1)

- White Paper (1)