Replique and Miele announce partnership to 3D print exclusive accessories

- Replique’s secure 3D printing platform is integrated into the Miele online shop, enabling quick and cost-effective entry to market.

- Replique and BASF 3D Printing Solution (under the brand Forward AM) are the first to implement a Good Manufacturing Practice (GMP) for 3D printing of polymer parts for food contact.

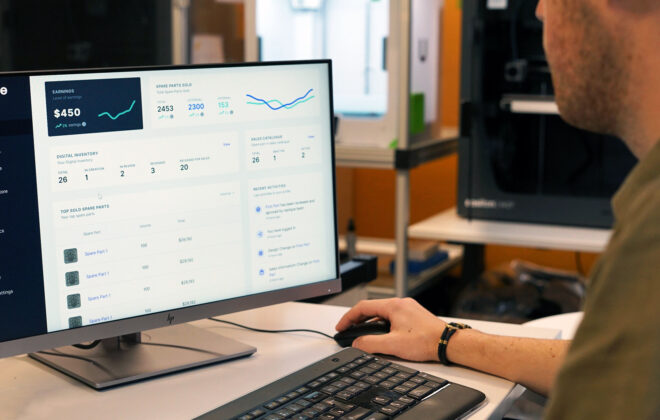

- By constantly digitally monitoring all manufacturing processes, Replique meets the high quality standards demanded by Miele.

Mannheim, Germany – June 21, 2021. Replique, a Mannheim based venture of the BASF business incubator Chemovator, announces a partnership with Miele, a German premium home appliance manufacturer. Under the terms of the partnership, Replique receives the exclusive right to produce and ship high-quality 3D printed accessories from Miele using its decentralized production network. Miele can now launch new products with Replique’s 3D printing platform. Thanks to the capability for digital storage and on-demand production, Miele is granted the flexibility to provide customers new accessories quickly and cost-efficiently from a batch size of just one. With Replique’s end-to-end solution, Miele benefits from an easy process integration that connects existing ordering and e-commerce solutions, automatic order processing and expert knowledge in industrial grade 3D printing.

Realizing the vision of 3D printed accessories

In May 2020, Miele started its 3D4U project to provide customers with free designs of 3D printable accessories. Due to the increasing demand, the idea arose to offer such products to those customers who do not have their own 3D printers. With Replique, this revolutionary idea is now becoming a scalable business model. Physical accessories no longer need to be stored in large quantities in a warehouse. Instead, the designs are stored in a digital inventory and are produced on-demand using the latest 3D printing technologies. Starting with three accessories on the Miele online shop – the coffee clip, the borehole cleaner and the valuable separator as vacuum cleaner attachments – the household appliance manufacturer can flexibly expand its product portfolio. “Miele and Replique are two pioneers in their industries who are taking the range of services from 3D4U to a new level,” says David Buhl, Manager Innovation Management Miele Room Care.

Material: Polyethylene terephthalate (PET)

Certification of 3D printing processes

By qualifying the printing processes in accordance with the required specifications, Replique meets the Miele quality standards. Additionally, the coffee clip is being certified for food contact by providing a manufacturing process in accordance with GMP.

“Certifying processes in 3D printing is a complex topic that has yet to be really considered in the field of food approval. Working together with our partner Forward AM we are the first 3D printing solutions provider to implement a 3D printing process according to GMP and can therefore guarantee high process reliability”, says Dr. Max Siebert, co-founder of Replique.

Easy process integration with a turnkey solution

With extensive experience in industrial production, Replique enables qualified 3D printing processes and support with material knowledge and quality assurance. Thanks to digitally supported order fulfilment and simple integration into existing processes (ERP, e-commerce, etc.), Replique provides easy access to 3D printing with minimal effort.

Miele highly values the complete service offering. “So far, competing companies have only offered fragmented solutions. Replique is the only partner who has in-depth knowledge of the entire process and the right network to offer a turnkey solution. Their business model is scalable and we expect to expand our business in Germany, Europe or even worldwide in a short period of time”, says Buhl.

Replique and Miele are already planning to expand the product range on the platform this year. For further information on this topic contact Dr. Siebert (+49 1525 6419938) or visit www.replique.io.

Do you want to learn more about our partner Forward AM? Explore their materials and qualification services!

About Replique

Replique was born from experts of the Data2Value team inside the digitization group of BASF. The team had the vision of digitizing spare parts and producing them on demand so that they can be available anytime and anywhere. To further develop this idea the team joined Chemovator GmbH, the internal incubator program of BASF, in the beginning of 2020. Replique now offers an industrial 3D printing platform that enables OEMs to provide parts on-demand to their customers through a global, decentralized and secured 3D printing network.

About Miele

Miele is the world’s leading manufacturer of premium domestic appliances including cooking, baking and steam-cooking appliances, refrigeration products, coffee makers, dishwashers and laundry and floor care products. Their product portfolio also includes dishwashers, washing machines and tumble dryers for commercial use as well as washer-disinfectors and sterilisers for use in medical and laboratory applications (Miele Professional). Founded in 1899, the company has eight production plants in Germany, one each in Austria, the Czech Republic, China, Romania and Poland as well as two production plants belonging to its Italian medical technology subsidiary Steelco. Sales in the 2020 business year amounted to around € 4.5 bn (thereof 29.5% in Germany). Miele is represented with its own sales subsidiaries and via importers in almost 100 countries/regions. Throughout the world, the family-run enterprise, now in its fourth generation, employs a workforce of around 20,900, of which approx. 11,050 employees work in Germany. The company has its headquarters in Gütersloh in Westphalia.

Contact Information

Replique.io – A Chemovator Venture

Dr. Max Siebert

Co-Founder

T +49 1525 6419938

E max.siebert@chemovator.com

www.replique.io

Related Posts

Categories

- 3D printing industries (6)

- 3D Printing Materials (1)

- Basics (3)

- News (1)

- Point of View (10)

- Press (20)

- Press (20)

- Sustainability (3)

- Technology (6)

- Uncategorized (1)

- White Paper (1)