5 Ways 3D Printing is Enhancing the Principles of Lean Manufacturing

Lean manufacturing is a powerful methodology to optimize processes and eliminate waste in production processes. It originated from the Toyota Production System (TPS) and has since been widely adopted by manufacturers worldwide. 3D printing, also known as additive manufacturing, is a game-changing technology, that offers new opportunities to fulfill the goals of lean manufacturing. This article will explore the ways additive manufacturing supports lean manufacturing by eliminating waste and increasing efficiency in the manufacturing process.

What is lean manufacturing?

At its core, lean manufacturing is about creating value by minimizing waste and using production resources efficiently. Waste, in the context of lean manufacturing, refers to any activity or process that does not add value to the end product or service, increase costs and decrease efficiency. Toyota’s Chief Engineer Taiichi Ohno has developed seven types of wastes, commonly known as the “7 Wastes” or “Muda” in Japanese.

- Overproduction: Producing more than what is needed

- Waiting: Parts, materials or information are not available, when needed, resulting in delays and inefficiency

- Transportation: Unnecessary movement or transportation of goods

- Excess inventory: Holding more inventory than necessary ties up capital, increases storage costs and can result in obsolete or wasted inventory

- Motion: Unnecessary movement or motion of people, equipment or materials

- Over-processing: Doing more work than necessary can lead to unnecessary costs, time, and effort

- Defects: Products or parts that do not meet quality standards, resulting in rework, scrap, or customer returns

How 3D printing supports lean manufacturing

3D printing in combination with decentral manufacturing, offers unique capabilities that can help eliminate or reduce many of these wastes. Following the 5 principles of lean manufacturing described below, additive manufacturing is an approach which definitely increases efficiency of value chains.

1. Identify Value: Focusing on customer needs

The first principle of lean manufacturing is value, which focuses on understanding and delivering what the customer truly values. 3D printing offers a unique advantage in the development and introduction of new products. Companies can use additive manufacturing to quickly prototype and test new designs without huge ramp-up costs to find out what the customer values. 3D printing further enables the production of customized and personalized parts that fulfill individual customer needs. This flexibility allows manufacturers to widen their product portfolio with niche products that provide significant benefits to specific customer segments, leading to a more customer-centric approach.

2. Map Value Stream: Reduce complexity with additive manufacturing

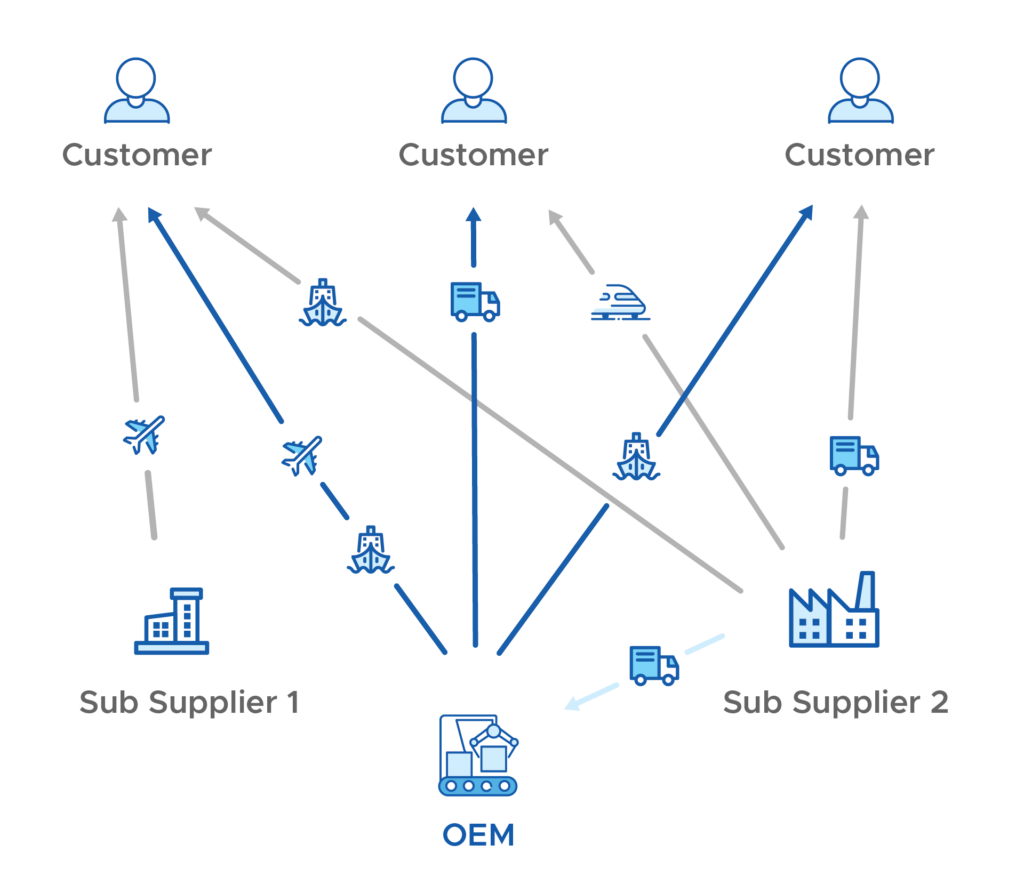

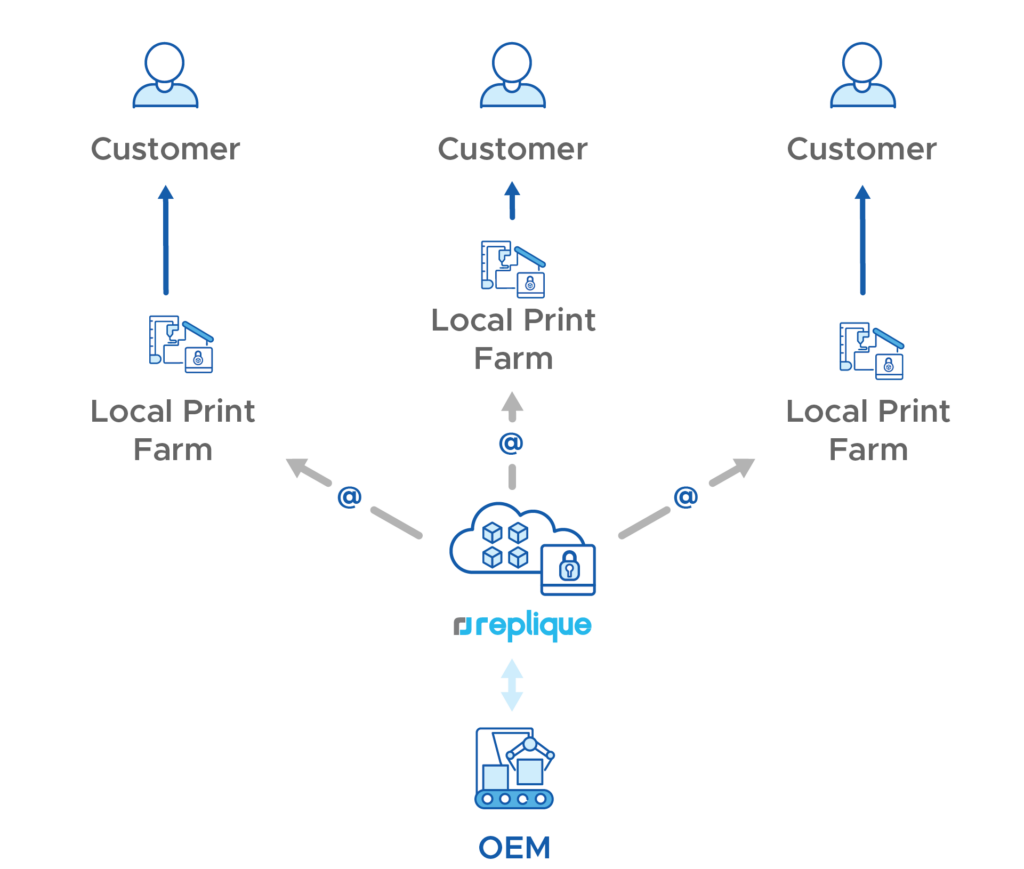

The second principle of lean manufacturing involves identifying and mapping the entire value stream from raw materials to the end customer. Traditional manufacturing methods often require multiple suppliers, transportation, and assembly steps, resulting in a complex and lengthy value stream. In contrast, 3D printing allows for the direct production of parts with minimal intermediaries, reducing assembly costs, and shortening the value stream. In combination with decentral manufacturing, additive manufacturing further eliminates the need for physical movement of parts between different locations. Parts can be produced directly at the point of use, reducing lead times, and leading to faster and more responsive manufacturing processes.

Traditional complex supply chains (left) vs simplified decentral 3D printing supply chain

3. Create Smooth Workflow: Eliminate unnecessary production steps

The third principle of lean manufacturing is flow, which emphasizes the smooth and uninterrupted flow of materials and information throughout the production process. While traditional manufacturing methods often require time-consuming tooling changes and setup adjustments to produce different parts, 3D printing, enables a continuous and uninterrupted flow of production as there is nearly no set-up included other than material change. This greatly minimizes waiting times and reduces unnecessary motion, leading to a seamless flow of production.

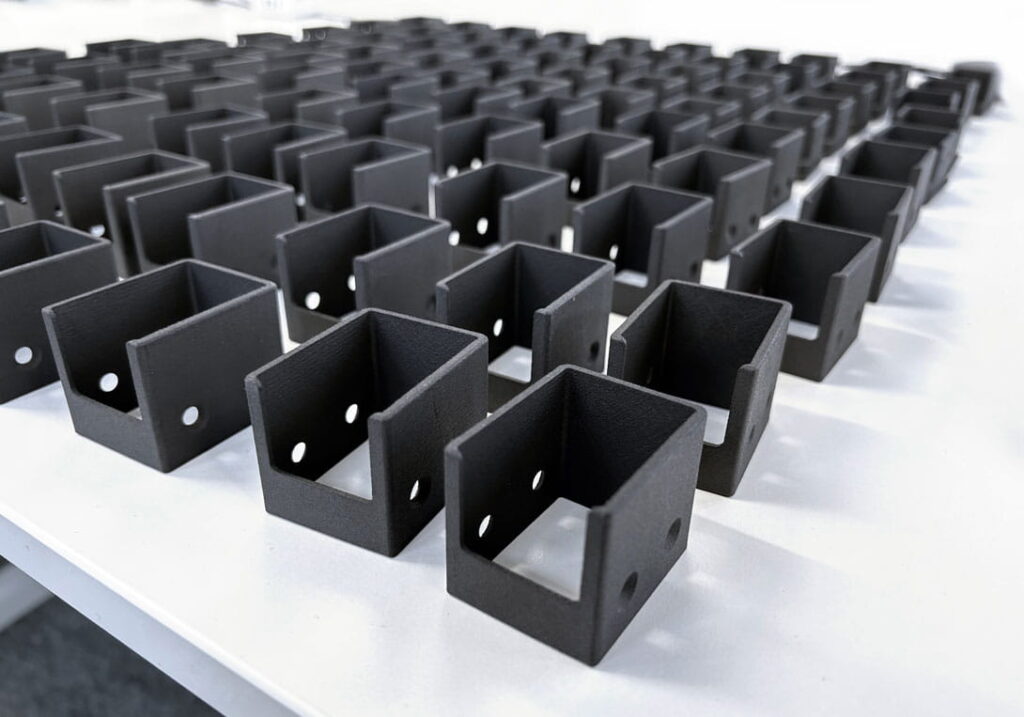

4. Pull Principle: Producing only what is needed

The fourth principle of lean manufacturing is pull, which focuses on limiting inventory while ensuring that all materials and information are available for a smooth workflow. Traditional manufacturing typically requires large production runs to be cost efficient, leading to overproduction and excess inventory. One of the key benefits of 3D printing however is the ability to produce parts on-demand, per customer order and based on actual demand. This pull-based production approach helps manufacturers to minimize waste in inventories and optimize production, ensuring that resources are used efficiently and effectively.

5. Continuous improvement: Faster design iterations

The last key principle of lean manufacturing lies in continuous improvement. As the technology continues to evolve rapidly, more and more parts can be produced using additive manufacturing. This presents companies with the opportunity to constantly seek out ways to improve their products and production processes. The speed and flexibility of 3D printing allow for easy and quick design iterations and enables manufacturers to swiftly implement improvements.

How platforms leverage the full benefits of 3D printing

While 3D printing alone already improves production efficiency, a decentral manufacturing approach increases those benefits even more. Additive manufacturing platforms such as Replique provide a streamlined and efficient way for manufacturers to connect with 3D printing service providers and access additive manufacturing capabilities on-demand. By combining on-demand 3D printing with a digital inventory, companies can easily get their parts produced in a safe and efficient manner.

With a digital inventory, companies can upload their 3D models with qualified production parameters that are locked for all future orders. In the digital inventory they have a comprehensive overview of all their 3D printable parts and past orders. Whenever a part is needed, either for their own use or by their customers, the order can be quickly processed through the digital inventory and printed by a partner located close to the end user. This approach eliminates the need for manufacturers to invest in expensive 3D printers and related equipment and allows them to leverage the expertise and capabilities of additive manufacturing service providers. Additionally, the reordering process becomes much smoother as all parts and associated production information are securely stored in a digital inventory. Paperwork and email transfer is not needed, reducing time and the risk of errors.

Want to leverage on-demand 3D printing for your business? Then contact us now:

Categories

- 3D printing industries (6)

- 3D Printing Materials (1)

- Basics (3)

- News (1)

- Point of View (10)

- Press (20)

- Press (20)

- Sustainability (3)

- Technology (6)

- Uncategorized (1)

- White Paper (1)