To buy or not to buy, that is the question. What sounds like a dramatic sentence from Shakespeare, is actually a serious concern manufacturers have when it comes to additive manufacturing/3D printing. The technology is now being used more widely, more applications arise and many companies are thinking about integrating the technology into their processes. With this the question arises, if they should outsource 3D printing or produce inhouse.

To say upfront, there is no simple answer and there are pros and cons for each option. However, this guide should help you in finding the right decision. We have established 6 factors you need to consider when deciding between inhouse and external 3D printing.

1. Location

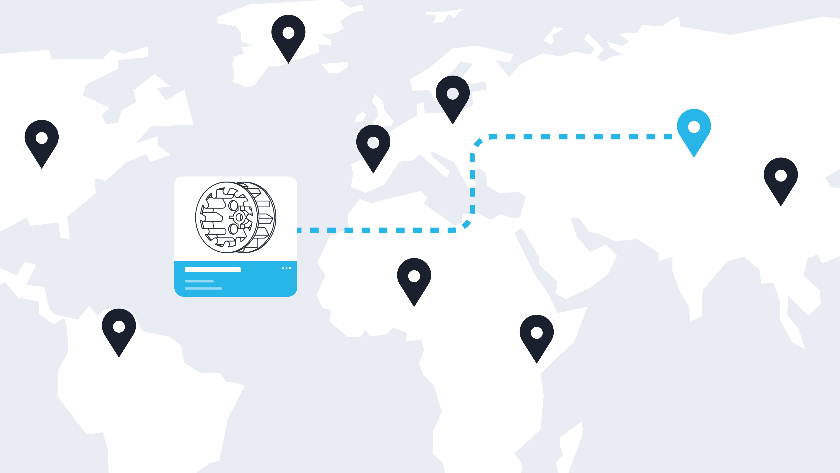

The location where your products are needed should play a big role within your decision making. If you only need to provide the parts within one country or region, having the printers centrally will probably be the best solution.

However, if you want to provide parts globally, shipping your parts to the other end of the world can get expensive, not even mentioning the current supply chain disruptions that could lead to difficulties in providing the parts at the right time. Engaging with multiple print farms located all over the world, or even with a 3D printing platform with a global printer network could be the solution.

2. Design flexibility

Design flexibility is one of the biggest benefits of 3D printing. When a product is still in the prototyping phase you want to produce a part, test it, make changes and print it again. This is easiest and quickest when doing inhouse 3D printing, due to the fact that here you can implement design changes very fast. When outsourcing additive manufacturing, it can take longer to make changes as parts need to be shipped, printers need to be available etc. This would not be a problem for small series production, since at this stage the design is fixed.

3. Scalability

To decide on the scalability of inhouse and external 3D printing we mainly look at 2 things:

- Amount of different designs. Due to the constant increasing amount of printing technologies and materials the printer-material combinations are endless at the moment. If you plan to produce a large array of different products this would most likely mean that you need different materials and printing technologies, and so you would need to purchase multiple different printers. Also, post-processing options have to be checked internally. In this case, outsourcing is the better solution to reduce complexity. If you just produce a limited number of designs, ideally in the same printing technology, inhouse 3D printing could be the optimal solution.

- Amount of parts. If you need large quantities of parts, it might be smart to outsource it, because it will turn into an operation on its own to produce them inhouse. Same goes for when you need e. g. 1-2 parts per week. It does not make sense to purchase a printer for the low amount. For mid-range volumes, that fit within your printer’s capacity, inhouse 3D printing would be the best option.

4. Investment

While there are budget-friendly desktop 3D printers on the market, for some technologies like FDM and SLA, you might also need high-end AM systems that require significant upfront investments. And not only the printers, but also maintenance, training of employees and material procurement will contribute to the overall cost. You will need the space for the 3D printers and maybe also new employees to work with them. This will not only lead to higher costs, but also higher risk as they are part of your fixed cost structure.

If these expenses are not justified by production volume or innovational power, you might consider working with a print farm or platform.

5. Capability (Knowhow & Quality Assurance)

Additive manufacturing differs highly from other manufacturing methods and there are several design and production guidelines that you have to fulfill to receive high-quality parts. If you lack the expertise and do not have the resources or time to train your stuff and develop the knowhow internally, outsourcing might be the better option. This way you can be assured that your parts are printed in the right quality.

6. Timeline

Setting up an internal printing service will take time. Buying and installing printers is a matter of hours/days, however training employees and setting up processes is something that will take weeks/months. In case you have a tight timeline, external 3D printing could be the better option.

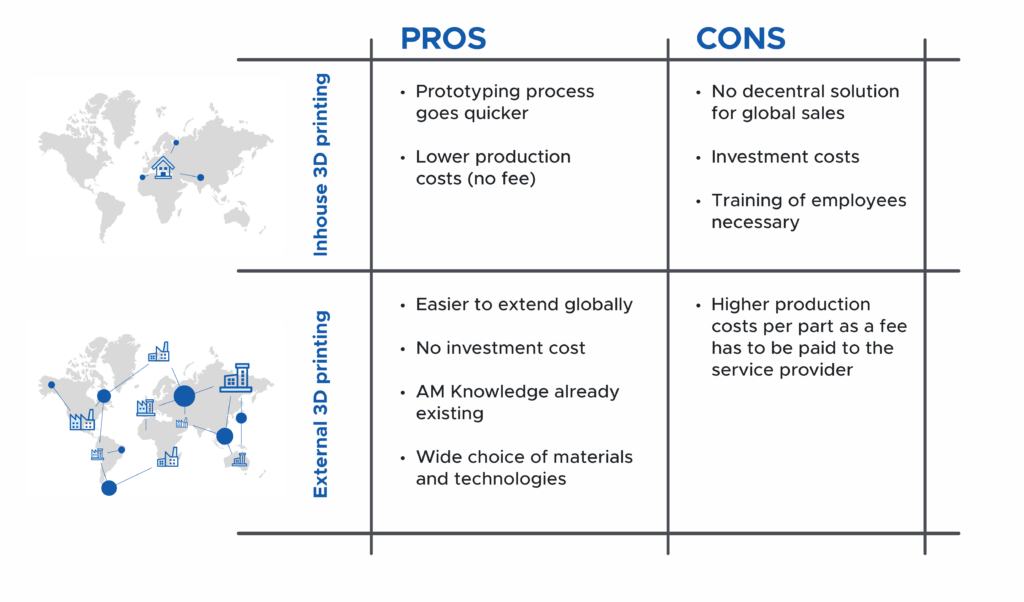

Overview Pros and Cons of Inhouse vs. Outsourcing 3D Printing

Both inhouse and external 3D printing have its pros and cons, depending on your use case. You can find a short summary of the main decision parameters below.

Why not combing both solutions?

It is impossible to give an answer whether inhouse or outsourcing 3D printing is the better option. In some cases, combining both solutions might even be the right fit. You produce certain parts inhouse that you can handle with your own printer, while you order the rest of the parts externally. This might sound like it needs quite some coordination. With a digital platform like Replique however, this would be very easy. Within your personal platform you can connect your own inhouse printers, and can either select to print the parts there, or place an order and let the parts be printed externally by a 3D printing service bureau nearby the location where the parts are needed.