Qualification for 3D Printing

Leverage our onboarding services to make your 3D printing journey a success.

Benefit from expertise in additive manufacturing, materials, qualification and design.

Part Identification & Validation

Replique helps you identify 3D printable spare parts from an economic and technical point of view.

Not every spare part is suitable for 3D printing. Therefore, we thoroughly analyze spare part inventories, including technical and economic factors such as material properties, size, demand frequency and lead times. Usually this leads to around 7-10% of printable parts. In a next step we validate the spare parts in a test print and give a quote. Using this data, it is possible to save the part designs in our digital inventory, so they can be printed on-demand and decentral, leveraging our 3D printing network.

Material & Technology Selection

We support you in choosing the right material and technology for your application. You can also access our free material database to get a quick recommendation.

Additive manufacturing offers a wide range of different technologies, used for different purposes. They are liquid, powder or solid based. 3D printing allows the use of many different materials from thermoplastics, metals, ceramics and biochemicals. Based on your part requirement (e. g. stiffness, hardness, UV-resistance) we can choose the right material and technology for your parts or you can access our free material database with easy filtering options.

Simulation & Redesign

To produce lighter, stronger and more durable spare parts we offer simulation and design services.

We can use simulation to visualize the thermo-mechanics during manufacturing, leading to a production of high-quality and high-accuracy spare parts. If we see a potential for a better performance of your part, we can also redesign it, leading to lighter and more durable parts with increased lifetime. Thus, reducing energy, costs and CO2 emissions during the usage phase of your product.

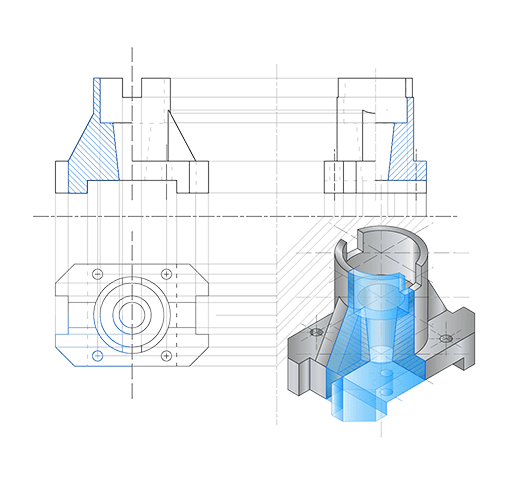

Convert Drawings & Reverse Engineering

We can convert your 2D drawings into a 3D model or reverse engineer your part to extract its design information.

Especially for older spare parts, design drawings are often not available anymore and CAD files are usually not existent at all. However, those legacy parts are a good fit for 3D printing as they cannot be manufactured in a cost efficient way anymore using traditional production methods. For this reason we are offering services for reverse engineering and the conversion of 2D drawings into 3D files. By digitally storing the design, you can produce spare parts for aging assets on demand.

Your 3D Printing Journey With Replique

Qualify the production process

We choose the right production parameters for reliable operations. If necessary, we also qualify the process together with a production partner.

Store parts in our digital inventory

After the onboarding process you can store all your spare parts virtually, leading to less costs in warehousing and higher flexibility.

Start operations leveraging our production network

After spare parts are qualified for additive manufacturing and uploaded to our inventory, our production network can start fulfilment.

Are you interested in knowing more?

Looking forward to hearing from you! Contact us now and we’ll get in touch.