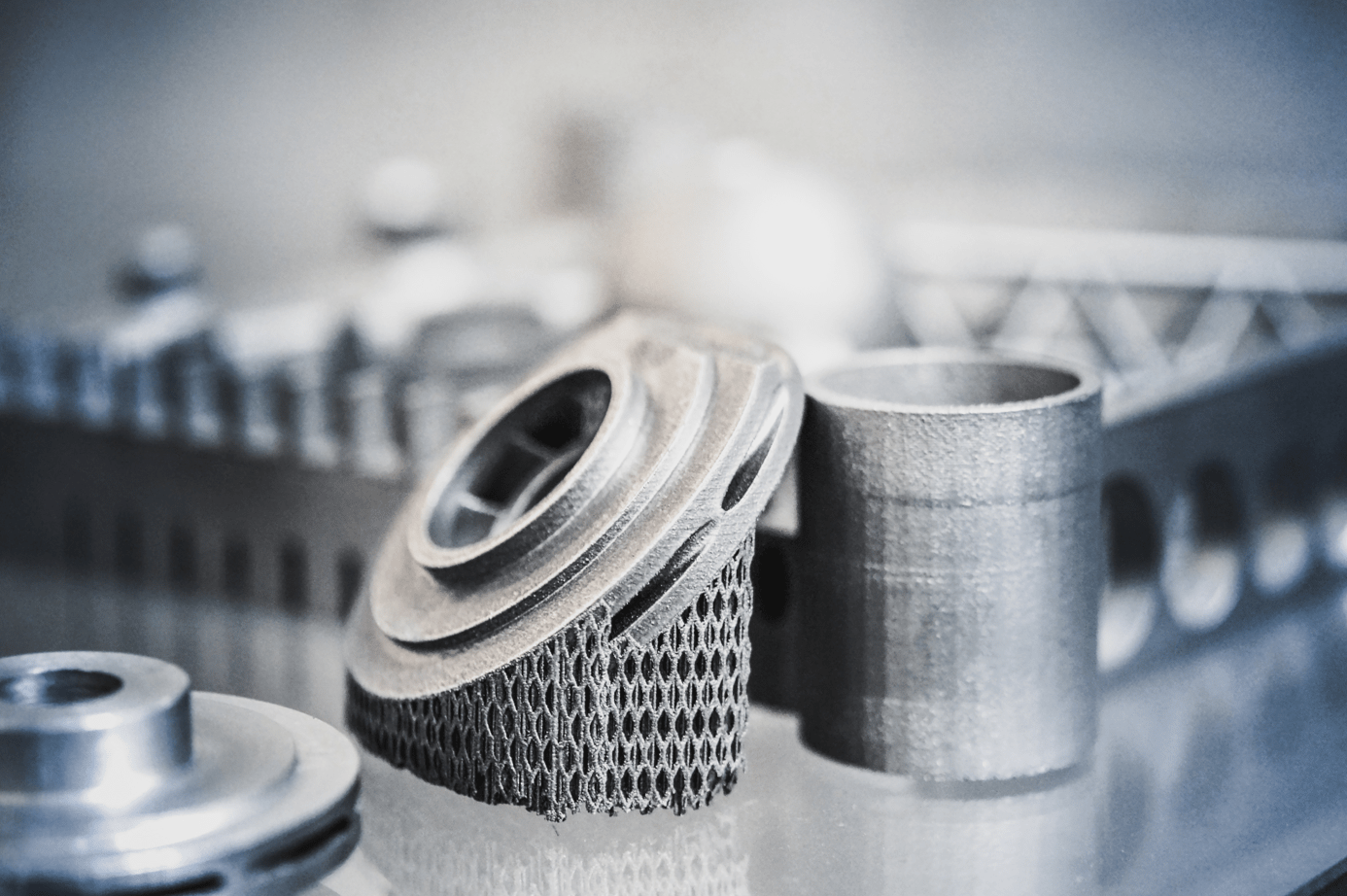

3D Printed Spare Parts

Deciding between customer satisfaction and cost efficiency is a thing of the past with 3D printing. Fulfill spare part demands quickly AND economically with decentral additive manufacturing and a digital inventory, where your parts are stored eternally.

CHALLENGE

Every spare parts manager knows the challenge. A growing product population on the market with many different product variations, that leads to a rising number of parts over the years. To provide every spare part throughout the product lifetime becomes complex. Having all parts available in a warehouse comes with huge inventory costs and the risk of obsolescence. If a spare part is not available however, this could lead to even bigger challenges. Spare parts have to be supplied with high minimum order quantities and express shipments. And even worse for critical spare parts: lead times are long. This could result in long downtimes and unsatisfied customers. How can this be solved?

HUGE INVENTORY COSTS

LONG LEAD TIMES AND DOWNTIMES

HIGH MINIMUM ORDER QUANTITIES

SOLUTION

Imagine you could provide spare parts on demand, anytime and anywhere – just with a click on a button. Without a physicial inventory and related costs, without keeping and maintaining tools, no mininum order quantities and huge shipment costs. Replique provides you the solution, combining a 3D printing ecosystem with a digital inventory. Once qualified for 3D printing, spare parts are stored eternally and can be produced everywhere worldwide, with lower costs than using traditional manufacturing.

NO TOOLING REQUIRED

PRODUCTION ON DEMAND

NO MINIMUM LOT SIZE

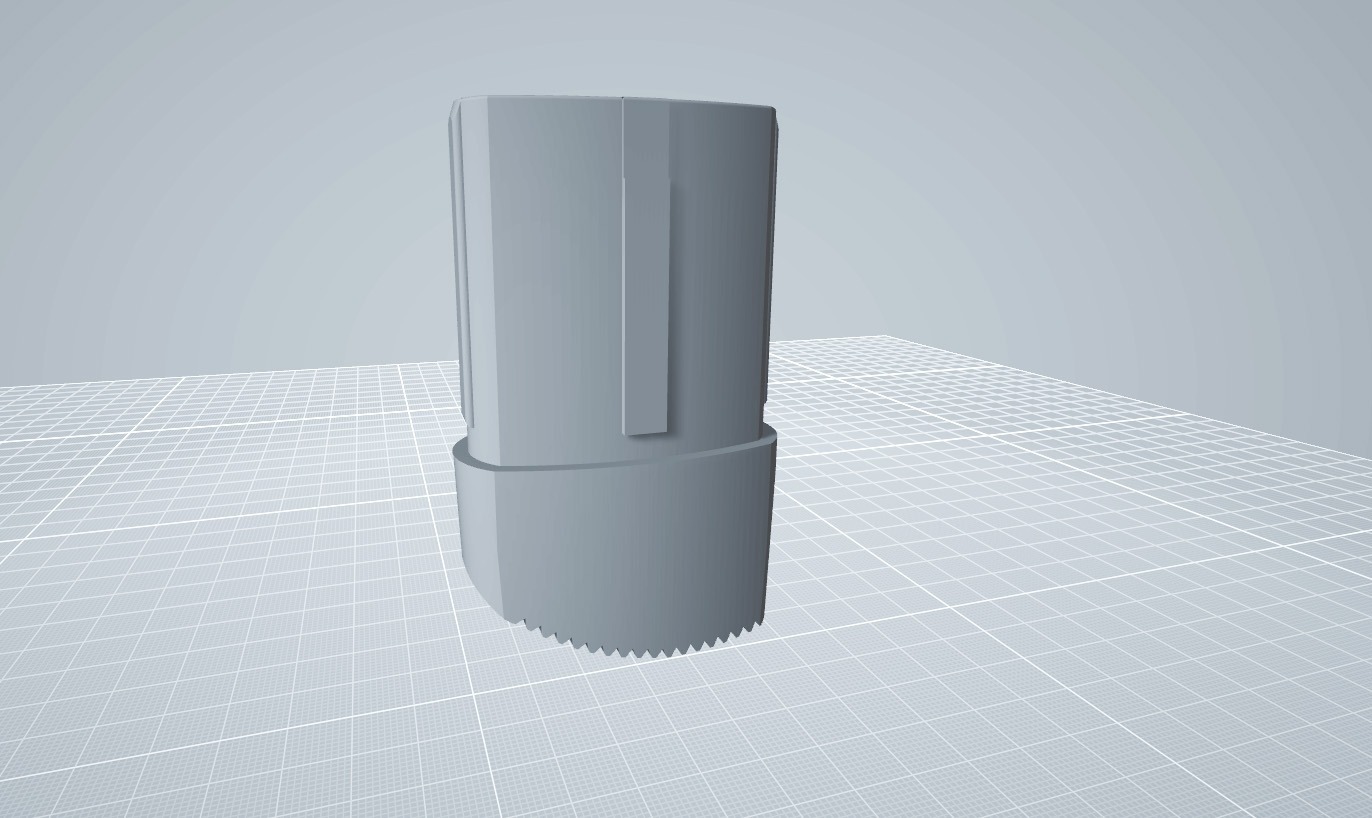

APPLICATION AT SIENA GARDEN

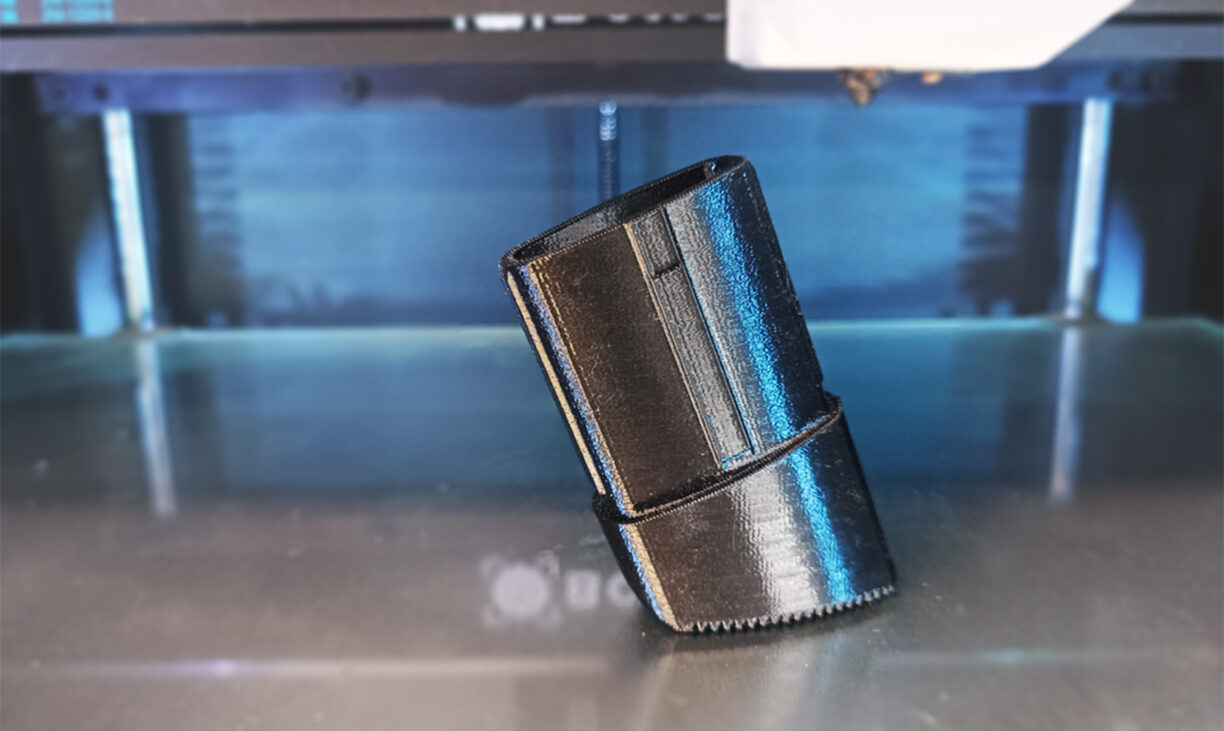

3D Printed Spare Parts for Garden Furniture, e.g. Foot Caps & Joints

How Siena Garden benefits from our services:

- Redesign for 3D printing

- Material and technology selection (requirements for outdoor usage)

- Qualification for additive serial production with testing

- 3D printing on demand via our network

- Webshop integration

- Order fulfilment and shipment

Spare parts can be 3D printed cost efficiently and provide the same quality as traditional produced parts

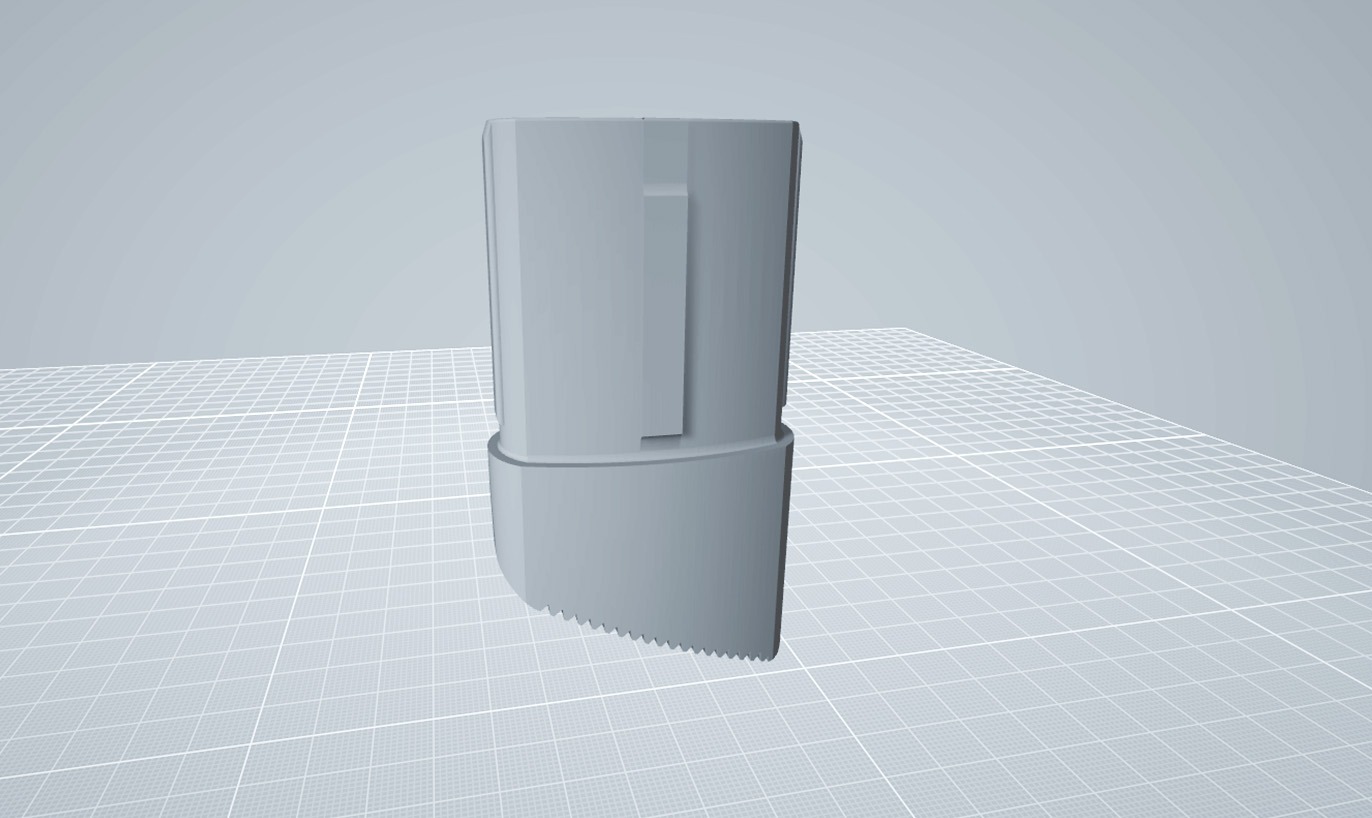

APPLICATION AT MAN

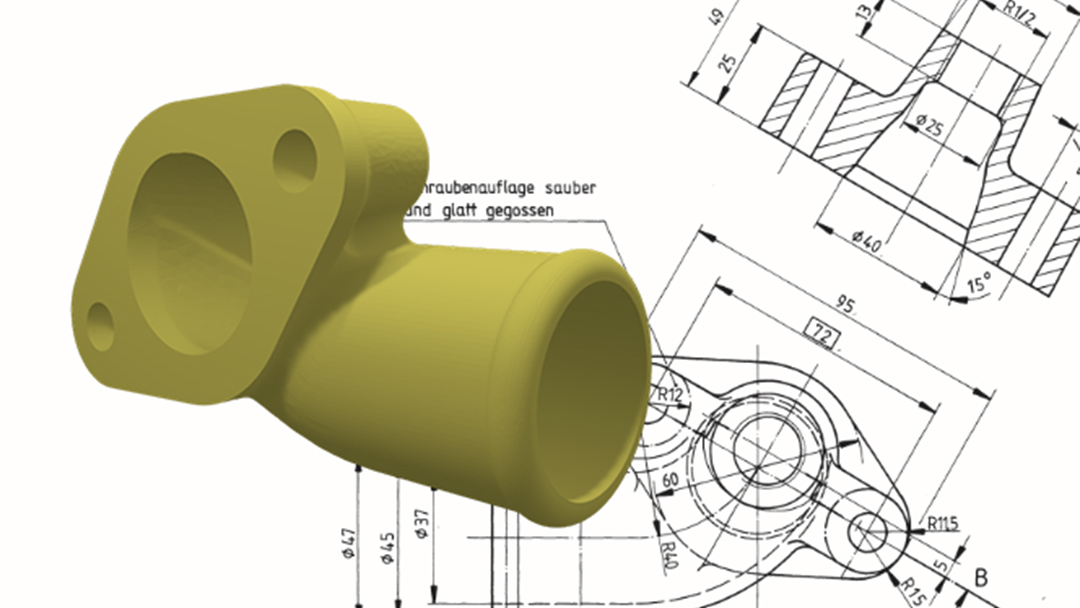

3D-printed bronze cooling water manifold for diesel marine engine

How MAN benefits from our services:

- Fast delivery of spare parts from inquiry to delivery in just 7 weeks

- No investment risks, as no fixed costs for molds and models required

- Metal 3D printing with technically equivalent material (bronze)

- Tensile tests at MAN’s Central Materials Technology department showed that the selected material has even better technical properties than the original

- Maximum flexibility, no minimum batch sizes and warehousing

“The collaboration with Replique was seamless from our initial contact to the moment we received the finished parts. It allowed us to promptly assist our spare parts customers, and we are already in the process of realizing another 3D printing project with Replique.”

Thomas Hauck, Spare Parts Logistics MAN

TRAIN PARTS ON-DEMAND

Replique cooperates with railauction.plus, the online marketplace for rail vehicles of DB Fahrzeuginstandhaltung GmbH, the maintenance division of Deutsche Bahn. With on-demand 3D printing, we ensure that companies receive spare parts exactly when they need them. Without minimum order quantities, storage costs and with minimal downtimes. Need a part quickly? Simply order via our quoting module on railauction.plus.

HOW YOU CAN BENEFIT FROM OUR 3D PRINTING SERVICES FOR SPARE PARTS

- 3D-scan services

- CAD construction and redesign for 3D printing

- Material and technology consultation

- Generation of printing parameters

- Digital warehousing

- Decentral 3D printing using our worldwide network

- Purchase quantity starting at lot size 1

- One-stop-shop, no previous 3D printing experience required