The Role of AI in Enhancing 3D Printing Quality and Scalability

3D printing is set for significant growth, with industry projections estimating an increase from $14.7 billion in 2023 to $58.7 billion by 2032. This rapid expansion reflects the technology’s growing role across various industries, from healthcare and automotive to aerospace. However, while 3D printing is advancing swiftly, it still has to face hurdles in scaling up and delivering consistent quality. Artificial Intelligence (AI) could be the transformative force needed to address these challenges and drive its adoption. Let’s explore how 3D Printing an AI work together.

3D Printing and AI: The Key to Quality and Consistency

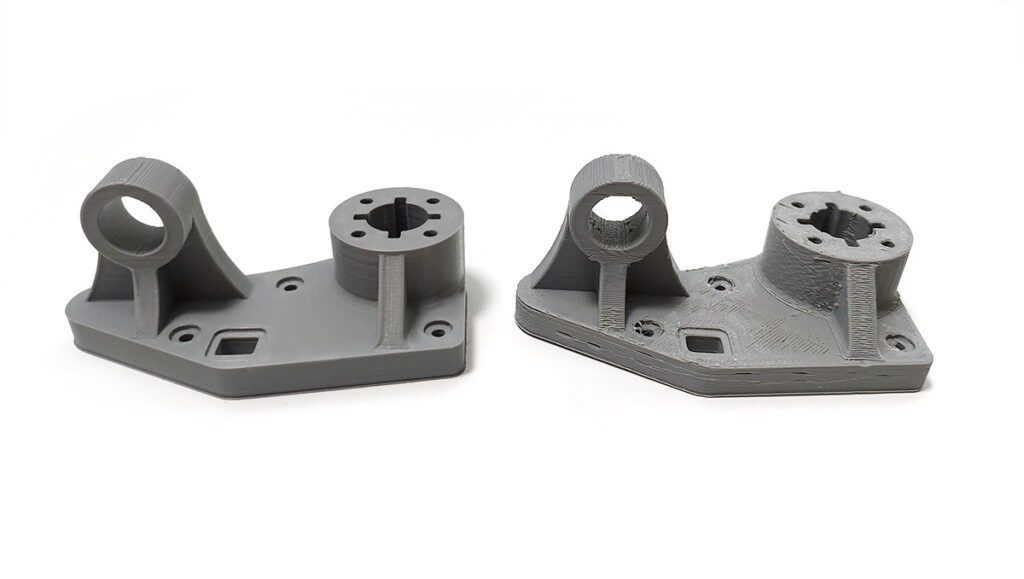

One of the primary challenges in 3D printing is achieving precision and consistency across prints. Variables like material selection, extrusion rates, and design intricacies can result in flaws such as cracks, warping, or incomplete parts. Traditionally, ensuring quality has required a trial-and-error approach that wastes time and resources. AI offers a solution by streamlining the process and enhancing quality control.

AI algorithms can monitor the printing process in real-time, detecting issues before they lead to defects. This is achieved through continuous analysis of sensor data and application of machine learning models trained on extensive datasets. By adjusting parameters on the fly, AI can prevent common issues like layer misalignment, thereby improving the overall print quality. This increased reliability is crucial for sectors like healthcare and aerospace, where precision is non-negotiable.

In addition, AI’s predictive capabilities reduce the need for repeated test runs, cutting down on material waste and saving time. As AI becomes more sophisticated, it enables even greater consistency across multiple machines, which is essential for scaling up production.

Scaling Up: AI’s Role in Automating 3D Printing Workflows

While 3D printing has proven its worth for prototyping and small-batch production, scaling up for mass manufacturing remains a challenge. Ensuring consistent quality across high-volume print jobs is difficult, especially when each machine has different operational nuances. AI-driven automation could be the solution that bridges this gap.

AI can coordinate multiple machines within a single workflow, optimizing conditions for each print job to ensure uniformity across production. Advanced algorithms also help in scheduling tasks, setting parameters, and monitoring progress to boost efficiency. By minimizing manual intervention, AI reduces the risk of human error and helps to keep costs in check. The ability to scale consistently makes AI-enhanced 3D printing more appealing for industries with high-volume needs, such as consumer goods and automotive manufacturing.

Generative Design: Reimagining the Creative Process with AI

Traditional computer-aided design (CAD) tools often don’t account for the unique requirements of 3D printing. This can lead to inefficient designs and lengthened development cycles. Designing for 3D printing is inherently different from traditional manufacturing, requiring a rethink of design principles. This is where AI-driven generative design comes into play. Generative design tools use AI to explore all possible configurations based on given parameters. This can result in innovative and efficient designs that would be challenging for humans to conceptualize alone.

These AI-generated designs are optimized for strength and material efficiency. Often it mimicks organic structures found in nature, such as bone or honeycomb patterns. These structures are not only lighter but also stronger. This makes them ideal for industries like aerospace, where weight reduction is a top priority. Autodesk’s Netfabb is one such tool that uses generative design to help manufacturers find optimal design solutions for 3D printing, reducing the need for endless simulations and manual adjustments.

The implications are significant. Generative design enables engineers to input specifications like weight limits, material constraints, and mechanical requirements, and let the AI handle the rest. This automation of the creative process lowers the barrier to entry, making 3D printing accessible to designers with varying skill levels. As a result, companies can bring products to market faster, with reduced development costs.

AI-Driven Democratization of 3D Printing

As AI automates complex processes, it makes 3D printing more accessible to a broader audience. Tasks that once required specialized skills can now be managed with AI-powered tools, allowing designers and engineers of all levels to create sophisticated parts with ease. This democratization of design has the potential to expand the applications of 3D printing across a wider range of industries.

AI’s role in monitoring, predicting, and preventing errors, combined with its ability to automate design and streamline production, positions it as a critical enabler for the future of 3D printing. As AI continues to evolve, it could unlock new possibilities in additive manufacturing, making the technology more reliable, scalable, and cost-effective.

A Look to the Future

AI’s influence on 3D printing is already evident in high-tech industries like healthcare, where it helps create custom prosthetics, and in aerospace, where it optimizes lightweight structures for aircraft. With AI’s help, 3D printing could overcome its current limitations and transition into a mainstream manufacturing method, enabling innovations that were once out of reach. As the sector grows, AI will likely be a pivotal factor in ensuring that 3D printing lives up to its full potential. While AI might seem like a buzzword in some contexts, in 3D printing, it is in fact a game-changer.

Contact us, if you want to learn how to use AI for your business!

Categories

- 3D printing industries (6)

- 3D Printing Materials (1)

- Basics (3)

- News (1)

- Point of View (10)

- Press (20)

- Press (20)

- Sustainability (3)

- Technology (6)

- Uncategorized (1)

- White Paper (1)