How To Streamline Material Selection in 3D Printing

3D printing has revolutionized small-scale production, but choosing the right material remains a significant challenge due to the vast array of options. Replique’s Material Hub addresses this issue, simplifying and optimizing the material selection process.

Why Material Selection Matters in 3D Printing

Selecting the correct material is crucial for the success of 3D printing projects. The chosen material must meet various specifications, such as mechanical strength, flame resistance, electrical insulation, and chemical resilience. Proper material selection ensures high-quality performance and avoids issues like poor dimensional accuracy, low strength, or poor UV-resistance. Therefore, having a reliable source of material information is vital for making informed decisions tailored to specific applications.

Challenges in Manual Material Selection

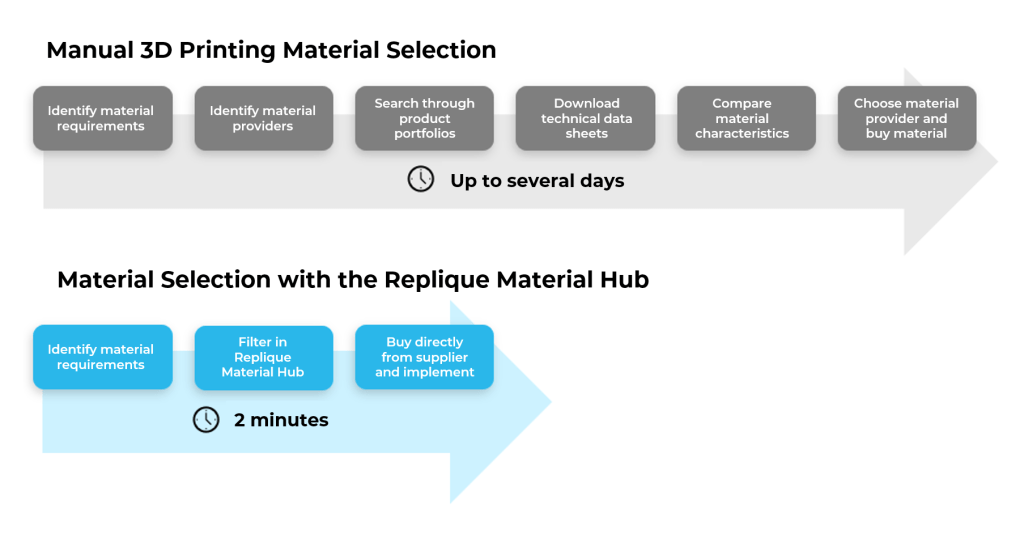

Finding the right material however requires extensive research on manufacturer websites, datasheets, and forums. This time-consuming process can result in wasted hours with no satisfactory outcome. Furthermore, converting traditional materials to 3D printing materials is challenging, as properties and applications are not always directly transferable. This often leads to delays and costly iterations.

Replique Material Hub: An Efficient Solution

Replique’s Material Hub offers a comprehensive solution to these challenges. It provides a user-friendly platform with an extensive database of more than 500 materials from more than 25 manufacturers, allowing users to filter and search for materials based on specific criteria such as type, mechanical properties, chemical resistance, thermal stability, and even specific certifications. This reduces time spent on research and avoids unnecessary material tests and misprints. To ensure quality and accuracy of the data, Replique collaborates closely with the material manufacturers.

Experienced users can perform detailed searches on the Material Hub, while beginners can use simple queries to find suitable materials. This democratizes access to the tool, making it accessible for users with varying levels of experience. Once a material is selected, users can request quotes for manufacturing parts or contact material providers for more information.

The application can further integrate with other systems via APIs, allowing seamless incorporation into existing workflows of production companies, material manufacturers, service providers and printer manufacturers alike.

While focusing on polymers at the moment, Replique plans to add metals soon, catering to a broader range of needs.

Key Benefits of the Replique Material Hub

- Save Time: Gain rapid access to an extensive material hub, cutting down research time from hours to just minutes.

- Boost Quality: Make well-informed decisions with comprehensive data, enhancing the quality of printed parts.

- Expand Knowledge: Explore a diverse range of materials and their applications.

- Reduce Costs: Efficient material selection lowers project costs and eliminates the need for internal printing trials and qualification processes.

- Increase Flexibility: Perform detailed or simple searches tailored to individual requirements and experience levels.

- Enhance Decision-Making: Utilize reference cases, certificates, and other valuable information that can be downloaded via the Replique Material Hub to support material selection.

Want to leverage the benefits of quick and easy material selection for your 3D printing projects?

Categories

- 3D printing industries (6)

- 3D Printing Materials (1)

- Basics (3)

- News (1)

- Point of View (10)

- Press (20)

- Press (20)

- Sustainability (3)

- Technology (6)

- Uncategorized (1)

- White Paper (1)