Great to see you again!

Thank you for your interest in Replique!

Take your sample set and learn about the benefits of each material by simply matching the letters of the samples with the ones on this page.

This is just a small range of materials we offer within our network. If you want to find out more about other materials or tell us about your requirements, simply get in touch!

Navigate to a material by simply clicking on one of the images below.

PP Polypropylene

Polypropylene or PP is one of the most widely used standard plastic materials. The stiffness of polypropylene makes it very suitable for technical applications and durable plastics. Polypropylene also exhibits excellent chemical resistance, watertightness, low moisture absorption and high elongation. The low cost makes it possible to expand 3D printing applications and volumes.

Benefits

- High ductility

- Exceptionally high rigidity

- Excellent chemical resistance

- High elongation at break (approx. 30%)

- Air and water tight

- Low cost

Applications

- Pipes and ducts for air and other media

- Water reservoirs and manifolds

- Economic and functional prototypes

- Multi-purpose industrial goods

Stainless Steel 316L

This metal was turned into filament, so it can be used in conventional FDM 3D printers. It combines design freedom with low cost, making metal 3D printing easier, faster and expandable for use cases where it has not been economically affordable before. The part is printed out of a filament that combines polymer and metal powder. After printing, the part undergoes debinding to remove the polymer. Once the polymer is removed, it undergoes a sintering process to give the metal its final properties.

Benefits

- Affordable metal 3D printing

- Fast production

- Compatible with FDM printers

- Industrial grade stainless steel

Applications

- Tooling

- Jigs and fixtures

- Functional prototypes

- Small series production

TPU 88A

TPU 88A is a polyurethane that offers strong, flexible and durable performance combined with excellent surface quality and level of detail. Parts have a stable white color, allowing easy finishing by smoothing, dyeing and coating. Typical applications include sports protective equipment, footwear, orthopedic models, automotive interior components and various industrial tools such as pipes and clamps.

Benefits

- High elasticity, rebound and resistance to fatigue

- Excellent surface quality and level of detail

- High process stability and easy-to-print

- Easy finishing incl. smoothing, dying and coating

Applications

- Sports protection equipment

- Footwear

- Orthopaedic models

- Car interior components

- Tools, grippers and pipes

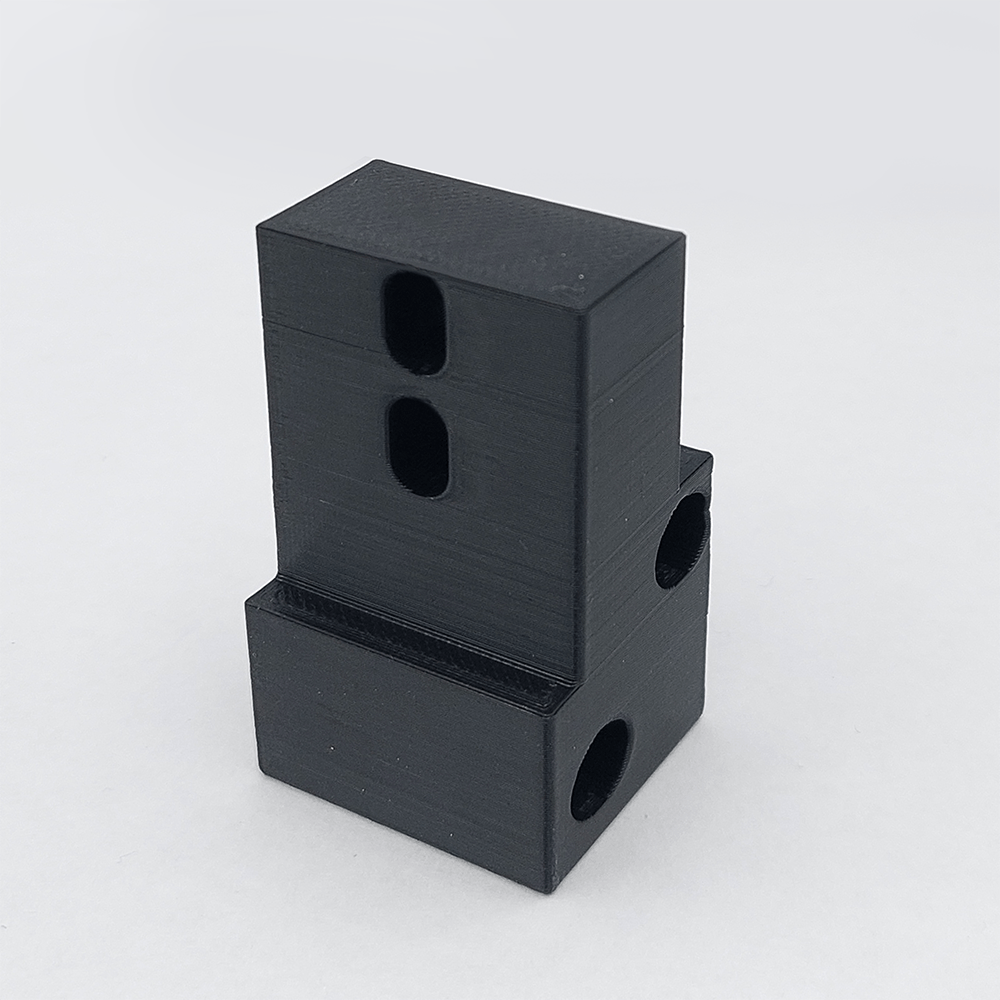

ABS+

ABS+ is an engineering material that enables a very efficient 3D printing process. It is a simple to print material with good properties: very tough, hard and rigid, with chemical and abrasion resistance. It has therefore become one of the most widely used materials in FDM printing. ABS+ is not UV resistant. If UV resistance is needed, other materials such as ASA – with similar properties, but more difficult to print – are a good alternative.

Benefits

- Easy to print

- Direct printing on heated glass or print bed surfaces

- High heat resistance

- Adheres to water soluble support

Applications

- Jigs and fixtures

- Automotive part

- General use

PAHT CF15

PAHT CF15 is a high-performance 3D printing filament with advanced mechanical properties, high dimensional stability and chemical resistance. It is made of polyamide with 15% carbon fiber. It is compatible with soluble support materials achieving great design freedom for parts that are used in challenging environments.

Benefits

- High chemical resistance

- High temperature resistance, up to 150 °C

- Strong, rigid components

- High dimensional stability

- Low moisture absorption

Applications

- Automotive / transportation

- Complex geometries in challenging environments

- Strong highly rigid parts

Aluminium AlSi10Mg

Aluminium AlSi10Mg is a widely used alloy in Additive Manufacturing and metal casting. It combines good strength and thermal properties with low weight and flexible post-processing possibilities. Different heat treatments can be applied to modify properties like ductility or conductivity.

Benefits

- Good strength and hardness

- High corrosion resistance

- Good thermal and electrical conductivity

- Properties could be modified with heat treatments

Applications

- General engineering components

- Lightweight designs

- Aerospace and automotive components

- Substitution of cast AlSi10Mg parts

- Parts subject to high loads

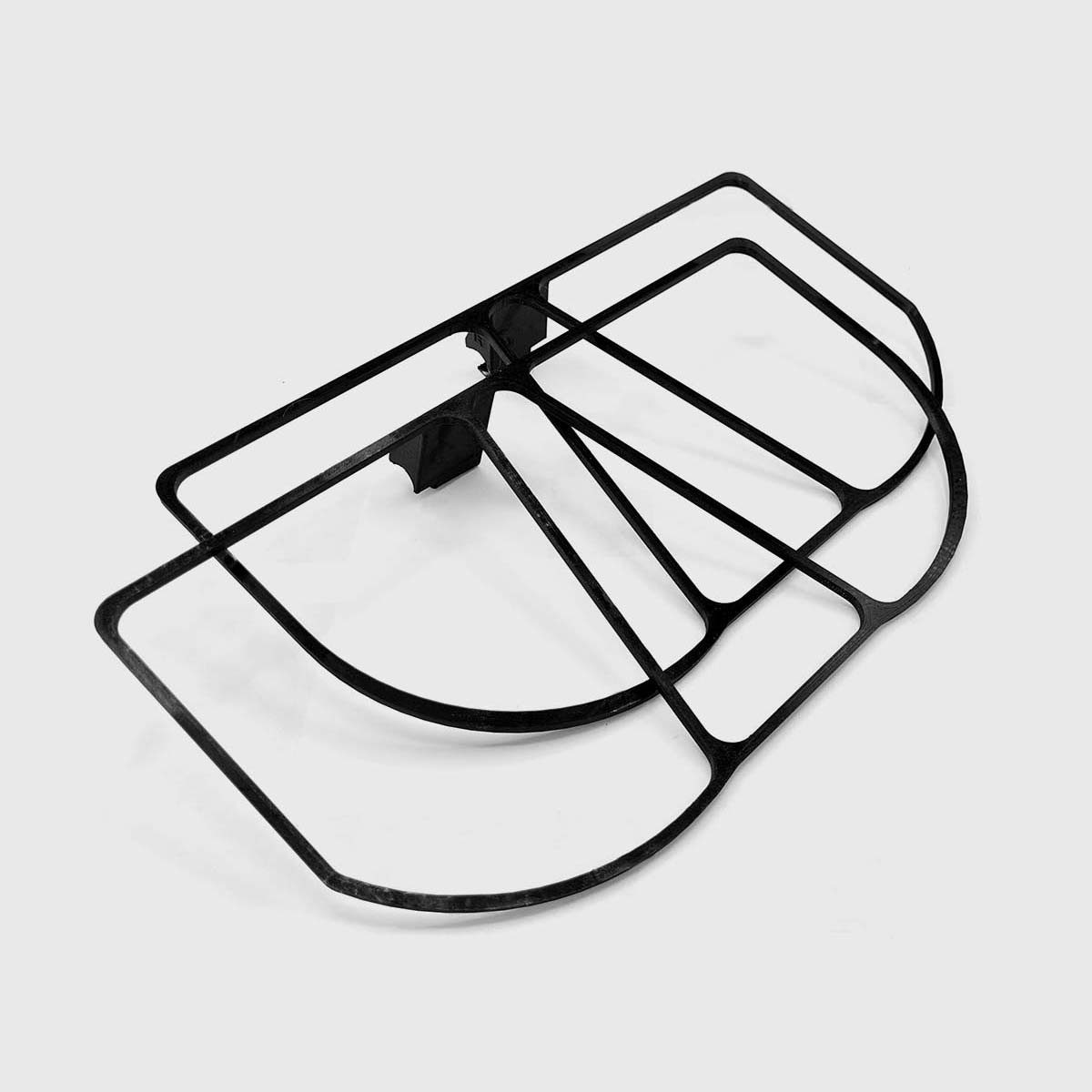

TPU 64D

TPU64D is a material that combines high strength with high flexibility. This material belongs to the thermoplastic polyurethanes. TPU64D has a high resistance to oils, greases and ozone, as well as a high resistance to abrasion. It has a high elongation at break and high impact strength.

Benefits

- High resistance to oils, greases, oxygen and ozone

- High wear and abrasion resistance

- High impact resistance

- Compatible with water soluble support

- Good weather resistance

Applications

- Functional flexible parts

- Wear and tear application

- Tooling, jigs and fixtures

PEI 9085

PEI 9085 was developed for its superior flow properties, offering exceptional printing behavior, high thermal resistance, broad chemical resistance, strength and stiffness. With these unique properties, it’s usage is ideal in high-temperature environments such as automotive and aerospace. Because of its inherent flame retardancy and low smoke emission, it is well suited for electronics and electrical appliances.

Benefits

- Temperature resistance up to 186°C

- Excellent dimensional stability

- Flame retardancy with low smoke evolution

- Good chemical resistance (e. g. against automotive fluids)

- Long-term hydrolytic stability

Applications

- Aerospace industry

- Automotive industry

- Electronics

- All applications exposed to high temperatures

PA 11

PA11 or Polyamide 11 offers exceptionally high ductility and impact resistance for any application requiring strength and toughness. PA11 is a great choice for parts that need to withstand high mechanical stress such as hinges, automotive interior parts or structures such as outer fenders. Its balanced mechanical properties and biological origin make it a sustainable alternative for prototypes and replacement parts.

Benefits

- Easy processing

- Exceptionally high toughness

- Suitable for skin contact

- High impact resistance

- Wide range of surface finishes

Applications

- Car interior parts

- Bumper components

- Functional prototypes & spare parts

- Medium-load serial production parts

You like what you see? Ask us to check your part and get a quote!

Our engineers will analyse your part and provide you with the information you need to get your part produced cost efficiently and on-demand.