Customer Story

Miele

3D Printed House Appliance Accessories

fully integrated and produced on-demand with Replique’s additive manufacturing platform

3D printed accessories fully integrated and produced on-demand with Replique

Miele is the world’s leading manufacturer of premium domestic appliances including cooking, baking and steam-cooking appliances, refrigeration products, coffee makers, dishwashers and laundry and floor care products. With 3D4U, the premium household appliance manufacturer Miele is the first company in its industry worldwide to offer customers a larger series of 3D-printable accessories. Thanks to the technology they are able to quickly scale new products and provide best solutions for their customers.

“With 3D4U, we want to offer our customers additional benefits and implement ideas that we have not yet reflected in our extensive portfolio of accessories.”

David Buhl | 3D4U project manager at Miele’s Bielefeld plant | Miele

Challenge

Since 2020 Miele is providing their customers under the brand 3D4U free 3D designs for new and innovative accessories for their vacuum cleaners and household appliances. However, only consumers with an own 3D printer could make use of them and print the accessories. To scale the products new facilities would be needed. Further, deep AM knowhow is necessary for a repeatable 3D printing process. An end-to-end solution was needed to solve the challenge.

“Miele and Replique are two pioneers in their industries who are taking the range of services from 3D4U to a new level.”

David Buhl | 3D4U project manager at Miele’s Bielefeld plant | Miele

Solution

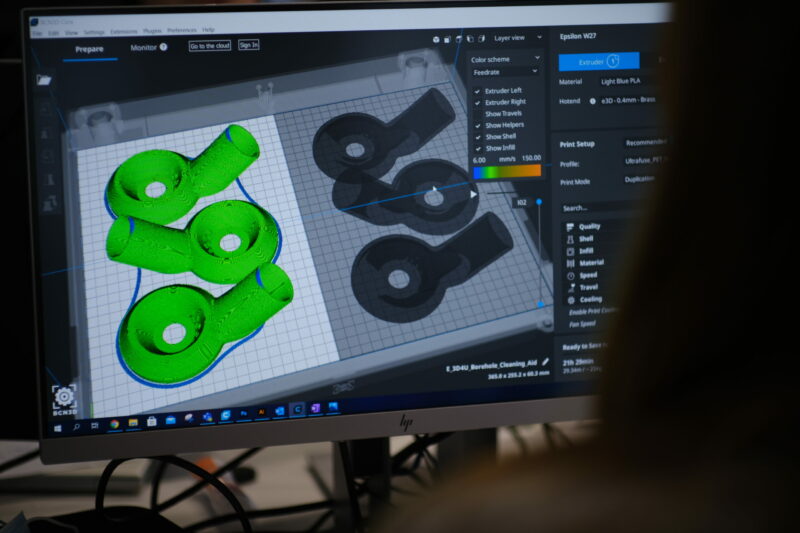

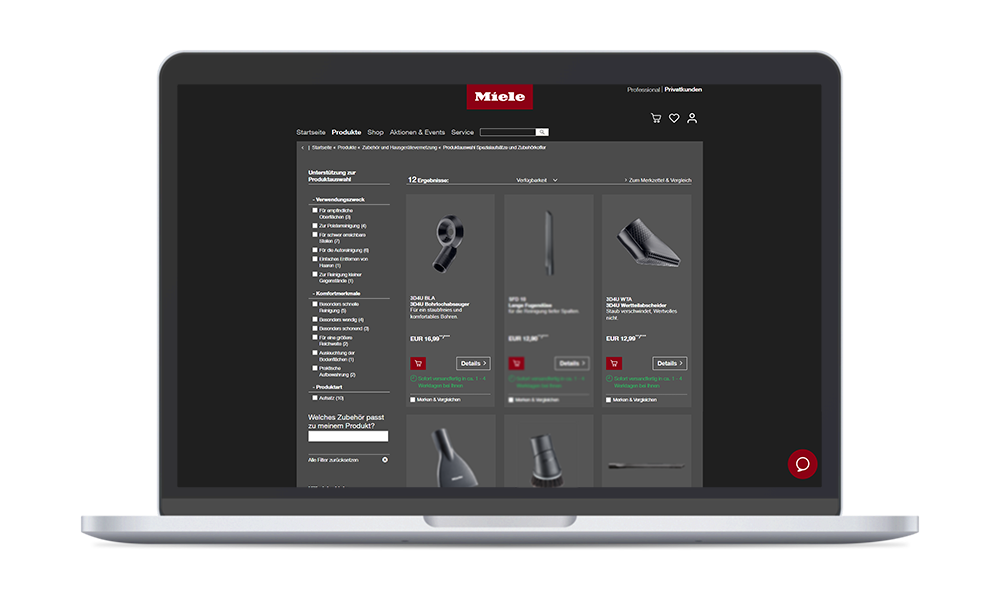

Through the 3D printing platform of Replique Miele was able to scale the project and provide their customers quickly and cost-efficiently with the new 3D printed accessories. Starting with three accessories – the coffee clip, the borehole cleaner and the valuable separator as vacuum cleaner attachments – the household appliance manufacturer can flexibly expand its product portfolio. With the full integration of Replique’s digital inventory platform they were able to provide the accessories on their own online shop leading to a high accessibility for their customers. Physical accessories no longer need to be stored in large quantities in a warehouse. Instead, the designs are stored in a digital inventory and after ordering them on www.miele.com, they are produced just-in-time and shipped directly to the customer.

Within the project, strong measures were taken to provide qualified processes for serial production, e. g. regarding technology, material and print parameter optimization. Working closely together with the material experts of Forward AM, brand of BASF 3D Printing Solutions, the 3D4U coffee clip made out of Ultrafuse® PET Black successfully passed the requirement for food contact according to LFGB and Regulation (EC) No. 1935/2004 and is produced in a manufacturing process in accordance with GMP.

Result

The project led to a fixed cost reduction by ~95% compared to making a mold for injection molding. The on-demand production avoids production of excess parts whilst ensuring the ability to supply at all times. The prices for the accessories (ranging from 12,99€-24,99€) are still competitive compared to other products in the same quality range. A quick design iteration of the parts could be adapted in the production process and qualification standards have been developed.

“So far, competing companies have only offered fragmented solutions. Replique is the only partner who has in-depth knowledge of the entire process and the right network to offer a turnkey solution. Their business model is scalable and we expect to expand our business in Germany, Europe or even worldwide in a short period of time.”

David Buhl | 3D4U project manager at Miele’s Bielefeld plant | Miele

INVESTIMENT COST REDUCTION

Fixed cost reduction by ~95% comparted to making an injection mold. Risk of losses is highly reduced.

TIME TO MARKET REDUCTION

A quick design iteration of the parts could be adapted in the production process and parts could be launched fast.

SEEMLESS INTEGRATION

3D printed parts are seemlessly integrated into the Miele webshop, where they can be ordered on-demand.

FOOD CONTACT SAFETY

The coffe clip passed the requirement for food contact according to LFGB and Regulation (EC) No. 1935/2004 and is produced in accordance with GMP.

Watch the video to learn more

Are you interested to know more?

Looking forward to hearing from you! Contact us now and we’ll get in touch.