The challenge of choosing the right process

When producing parts, deciding between CNC machining and additive manufacturing also known as 3D Printing can feel complex. Both have unique strengths during series production. CNC for precision and material priority, AM for flexibility and design freedom. Choosing the right method can determine your total cost, lead time, and product quality.

When CNC is better?

CNC machining is ideal for parts requiring tight tolerances, high surface finish, or certified metal properties. It’s especially efficient when producing simple geometries or medium batch sizes where setup costs can be spread across multiple parts.

CNC offers superior accuracy and mechanical properties, especially for structural parts requiring proven materials.

CNC becomes increasingly cost-effective once you reach 100–300 parts, depending on geometry and finishing requirements.

When Additive Manufacturing wins

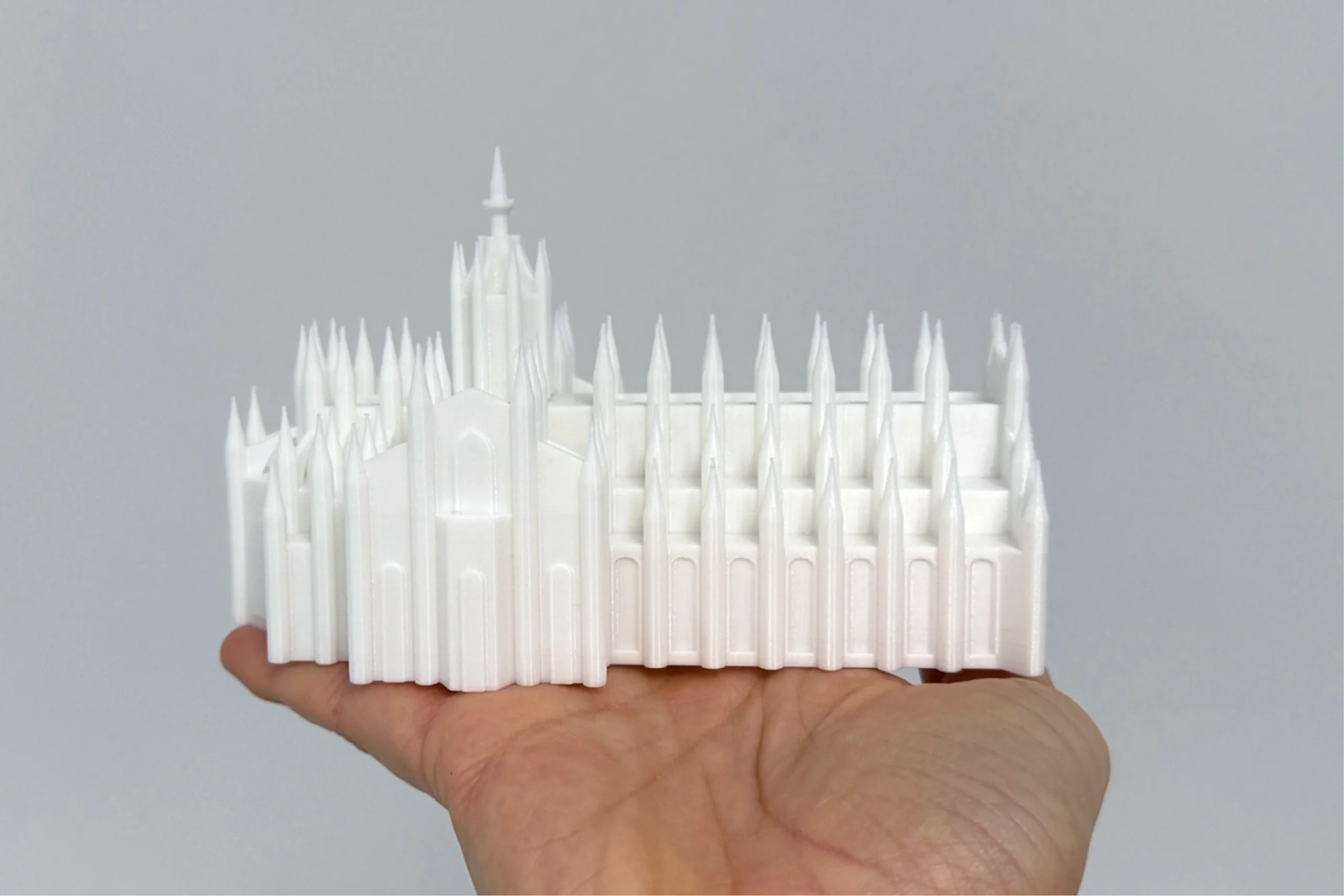

Additive manufacturing excels in low-volume, high-complexity, and customized production. It enables the creation of parts with internal channels or weight-saving lattice structures, or shapes that would be impossible or uneconomical with CNC. AM outperforms CNC in scenarios where design freedom, lightweighting, or rapid iteration are key.

For 1–100 units, AM typically offers lower total cost due to minimal setup and tooling. But even above it could be the better choice, depending on the needed design. It’s also ideal for on-demand spare parts, helping companies reduce physical inventory through digital warehousing platforms, such as Replique.

Technical comparison

While both technologies can deliver high-quality results, their characteristics differ in ways that directly impact manufacturability and performance:

| Parameter | CNC Machining | Additive Manufacturing |

| Tolerances | ±0.01 mm or better | Typically ±0.1 mm (process dependent) |

| Surface Finish | < Ra 1 µm achievable | Often requires post-processing |

| Material Range | Broad range of industrial metals and plastics | Smaller range, but expanding rapidly |

| Design Constraints | Limited to tool access | Complex, internal, or lattice geometries possible |

| Setup Costs | Higher due to tooling and programming | Minimal setup, no tooling needed |

| Waste | Higher due to subtractive process | Low, only the required amount of material is added |

This makes CNC a strong fit for high-precision or high-load applications. While AM is better suited for optimized, lightweight, or customized parts, such as covers, brackets, or fluid components

Conclusion

There’s no one-size-fits-all answer. For complex, low-volume, or decentralized production, additive manufacturing delivers unmatched flexibility. For precision, high-performance materials, or medium-volume series, CNC remains a strong choice.

Replique helps you find the right choice between both manufacturing technologies by analyzing part geometry, material, and production requirements. This way we optimize cost, lead time, and performance for every series production.