Defense organizations today face a new kind of challenge. They must stay agile and ready in a world where global supply chains can change overnight. Traditional manufacturing and logistics models often fail to deliver the speed and flexibility modern operations require.

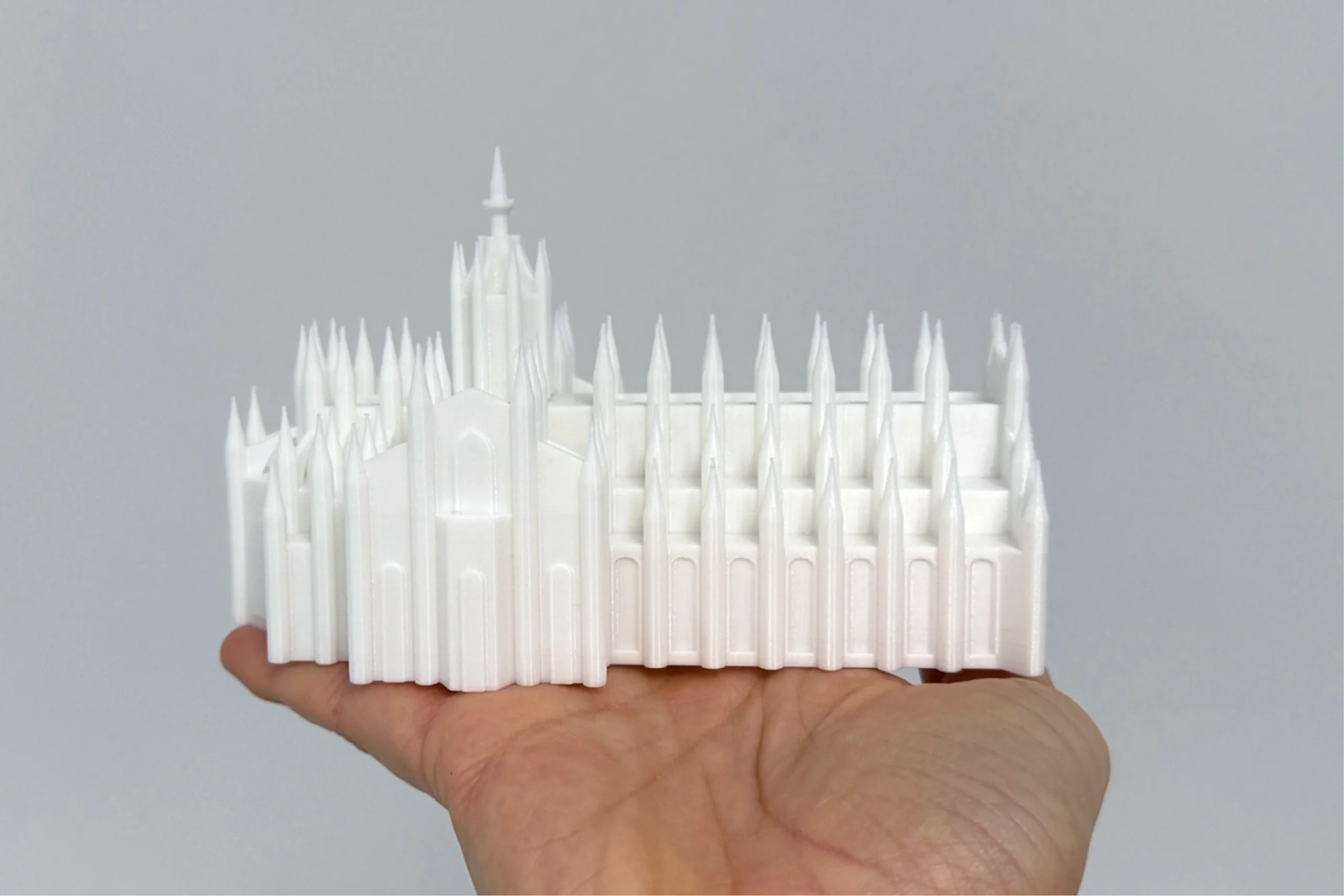

Additive manufacturing (AM) or industrial 3D printing offers a clear advantage. It enables on-demand production, supports small-batch manufacturing, and brings local production capabilities to the field. As a result, these qualities make AM a strong fit for defense logistics, especially in low-run and mission-specific scenarios.

Rethinking Defense Logistics

Military logistics depends on constant access to spare parts, tools, and equipment. Yet, these parts often come from suppliers scattered around the world. Consequently, delays, disruptions, and rising costs can leave critical systems grounded or out of service.

The additive manufacturing is a “key logistics enabler” for troops in contested environments, where traditional supply routes are not always available. AM allows parts can be produced directly where they are needed. Instead of waiting for deliveries from a central depot, operators can print a replacement part on-site. This way, AM helps to reduce lead times, lowers costs, and improve operational readiness.

On-Demand Production Where It Matters Most

Defense forces often need one-off or small-batch parts. Setting up traditional production for such low volumes is expensive and slow. In contrast, Additive manufacturing eliminates the need for molds or tooling, making small-run production practical and fast.

For instance, imagine a field unit printing a replacement valve or bracket within hours instead of waiting weeks. Portable 3D printers and digital part files make this possible. Furthermore, local manufacturing also reduces the environmental impact of transport and storage.

Digital Inventories Replace Physical Stock

One of the most powerful ideas behind AM is the digital inventory. Instead of storing thousands of physical parts, defence organisations can maintain a secure library of digital designs.

Through Replique’s digital inventory platform, authorised users can access certified designs, print parts locally, and maintain full IP protection. This model cuts warehousing costs and eliminates the risk of obsolete stock.

In addition, digital inventories strengthen security. When design data stays encrypted and traceable, sensitive information remains protected even across multiple production sites.

Versatile Applications for Defense Logistics

Additive manufacturing adds value across a wide range of defense support functions without entering areas like missiles or drones. AM “optimizes part performance while supporting secure, local production” in defense.

Common and practical use cases include:

- Spare parts for vehicles, ships, or equipment that are no longer produced.

- Custom tools and jigs for maintenance and repair tasks in remote locations.

- Lightweight components that reduce material use and improve performance.

Key Defense Components via AM and CNC

1. Spare Parts for Vehicles and Transport Systems- Military vehicles, naval vessels, and aircraft depend on a wide range of non-weapon spare parts to maintain operational readiness. These include brackets, mounts, housings, bushings, spacers, clamps, panels, covers, enclosures, and ventilation components. Many defense platforms remain in service for several decades, during which original equipment manufacturers often discontinue specific parts. Additive manufacturing enables the reverse engineering and rapid reproduction of such components, ensuring continued availability. CNC machining complements this capability by producing parts that require high mechanical strength, wear resistance, or tight dimensional tolerances, making the combined use of both technologies essential for long-term fleet sustainment.

2. Maintenance, Repair, and Overhaul (MRO) Components -A significant share of defense logistics is dedicated to maintenance, repair, and overhaul activities rather than new system production. These operations require specialized components such as tool holders, adapters, alignment tools, gauges, replacement fittings, protective caps, and custom jigs or fixtures. Traditional manufacturing methods are often inefficient for producing these items in small quantities. Additive manufacturing allows customized tools and fixtures to be produced quickly and cost-effectively, particularly in remote or deployed environments. CNC machining ensures the precision and durability required for critical maintenance tools, thereby reducing equipment downtime and improving overall operational efficiency.

3. Legacy and Obsolete Parts-Many defense systems continue to operate long after their original design life, creating sustained demand for legacy and obsolete parts. These include connectors, interface components, casings, structural supports, mechanical linkages, and interior components such as frames, mounts, and brackets. In many cases, original tooling and technical documentation are no longer available, making conventional re-manufacturing expensive and time-consuming for small production volumes. Additive manufacturing offers an effective solution for low-volume reproduction of such parts, while CNC machining is employed when regulatory compliance, material performance, or safety requirements necessitate higher precision and consistency.

4. Infrastructure and Base Support Components – Defense operations also rely heavily on a wide range of infrastructure and base support components for both permanent installations and temporary deployments. Typical examples include electrical enclosures, cable management systems, pipe fittings, fluid connectors, HVAC components, ducting, and mounting systems for equipment and sensors. Delays in sourcing these parts can disrupt operations and increase logistical complexity. Additive manufacturing enables rapid local production, reducing dependence on extended supply chains, while CNC machining remains critical for load-bearing or metallic infrastructure components that must withstand demanding operational and environmental conditions.

5. Lightweight and Ergonomic Components – Weight reduction and ergonomic design play an increasingly important role in enhancing personnel efficiency and reducing logistical burdens. Defense organizations frequently require lightweight mounts, supports, ergonomic grips, customized equipment holders, and protective housings for electronic devices. Additive manufacturing enables the production of complex geometries that reduce weight without compromising functionality and allows components to be tailored to specific user or mission requirements. Compared to subtractive manufacturing, AM also reduces material waste, contributing to more efficient and sustainable production processes.

AM is the Future for Defense Manufacturing

Additive manufacturing is changing how defense organizations think about production and supply chains. It complements traditional manufacturing by filling gaps where speed, flexibility, and localization matter most.

By focusing on logistics and low-volume manufacturing, rather than sensitive weapons systems, Replique helps defence organisations become more adaptable and sustainable.