Mehr als eine Beschaffungs-plattform

Denn das beste Angebot entsteht mit Ihrer Anwendung im Fokus.

- Optimale Technologieauswahl für Ihren Bedarf

- Weltweites Produktionsnetzwerk, flexibel skalierbar

- Vom ersten Prototypen über die Serie bis zum Aftersales

100+ Kunden vertrauen bei ihrer Beschaffung auf Replique

Ihr Partner für den gesamten Produktlebenszyklus

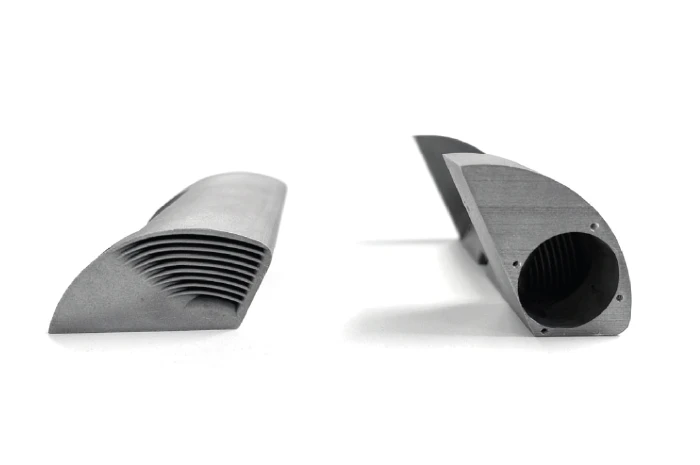

Prototypen & Piloten

Sie planen eine Markteinführung und benötigen dafür Prototypen?

Wir begleiten Sie vom Entwurf bis zur Nullserie – für eine schnelle Projektvalidierung.

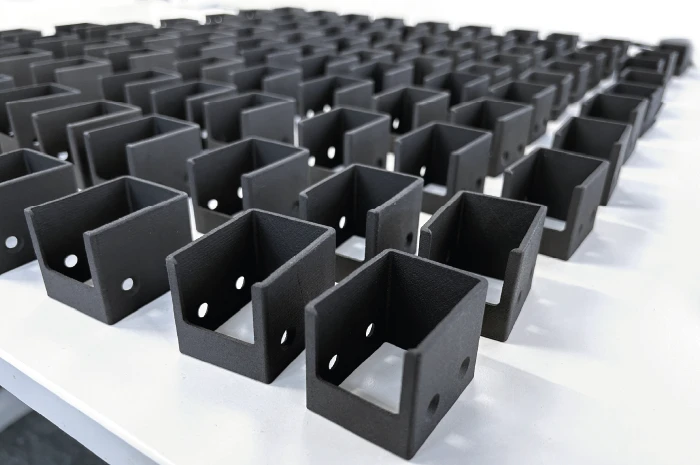

Qualifizierte Serien

Ihre Serienproduktion steht bevor, aber der passende Fertiger fehlt?

Wir beschaffen einbaufertige Teile nach Ihren Spezifikationen und technologieunabhängig in jeder Losgröße.

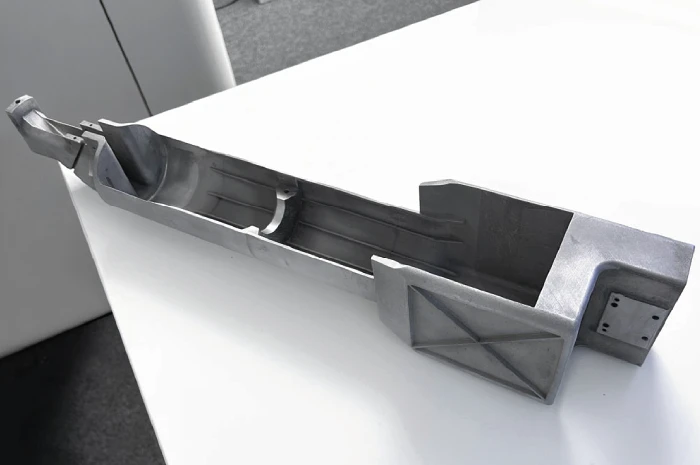

Ersatzteile & SOS-Bedarfe

Lieferant fehlt? Lieferkette gestört? Oder Sie wollen Ihr Lager optimieren?

Ob akuter SOS-Bedarf oder langfristige Strategie: Mit uns erhalten Sie Ersatzteile zuverlässig und on-demand.

Ihre Vorteile auf einen Blick

Beschaffungsaufwand um bis zu 90% reduziert

Ein Vertragspartner für alle Bedarfe. Keine langwierige Lieferantensuche, minimaler Abstimmungsaufwand.

Bauteile schnell und flexibel verfügbar

Kurze Lieferzeiten, lokale Produktion, Lieferung on demand. Egal, ob Einzelteile oder Serien.

Nach industriellen Standards gefertigt

Weltweites Netzwerk an zertifizierten Partnern. Mit branchenspezifischen Anforderungen vertraut.

Immer die passende Technologie für Ihre Anforderung

Unsicher, welche Technologie die richtige ist?

Aufgrund unserer langjährigen Industrieexpertise können wir Ihnen unterschiedliche Alternativen aufzeigen und geben eine Empfehlung ab!

Was unsere Kunden über uns sagen

“Die Zusammenarbeit mit Replique war vom ersten Kontakt bis zum Erhalt der fertigen Bauteile außerordentlich gut! Wir konnten so unseren Ersatzteilkunden schnell helfen und sind gemeinsam mit Replique bereits an der Umsetzung eines weiteren 3D-Druck-Projekts.”

Thomas Hauck

Spare Parts Logistics

„In der Serienproduktion bietet die Zusammenarbeit mit Replique entscheidende Vorteile in unserer Branche, wie zum Beispiel eine höhere Flexibilität in der Bedarfsplanung durch bedarfsgerechte Produktion oder die Möglichkeit, Änderungen schnell umzusetzen und individuelle Anforderungen mit speziell angefertigten Teilen zu erfüllen.“

Thyl Junker

Leiter der Entwicklung

„Die additive Fertigung ist mittlerweile ein zentraler Bestandteil unserer Lieferkette. Mit Replique profitieren wir von 3D-Druck- und Materialkompetenz sowie einem dezentralen Fertigungsnetzwerk, das alle relevanten Standorte und Technologien abdeckt. Ihre End-to-End-Dienstleistungen ermöglichen es uns, schneller und kosteneffizienter auf unterschiedliche Kundenanforderungen zu reagieren.“

Ben Boese

Ehemaliger 3D Printing Hub Manager