Introduction

The micromobility sector is undergoing a major shift toward profitability, moving beyond its early phase of rapid growth. One key factor driving this change is the rise of digital manufacturing platforms. According to McKinsey, these platforms could reduce fulfillment costs by more than 50% (Cities Today).

Replique is leading this transformation as it changes the way industrial parts are stored, shared, and produced. From prototypes, series to aftermarket, we offer agile and qualified production of parts and assemblies using technologies like 3D printing, CNC machining, injection molding, and more with a global network of more than 250 certified manufacturers.

The Cost Challenge in Micromobility

Manufacturing makes up nearly 30% of the total costs in the micromobility value chain (Zag Daily). Traditional methods often rely on complex supply chains, long lead times, and large capital investments.

Micromobility companies often invest significant time and resources managing contract manufacturers, long-term warehouse leases, and multiple service providers. As a result, micromobility providers struggle to scale efficiently and respond quickly to market demands. Therefore, reducing manufacturing costs and improving flexibility is essential for growth in this sector.

Replique’s Digital Manufacturing Solution

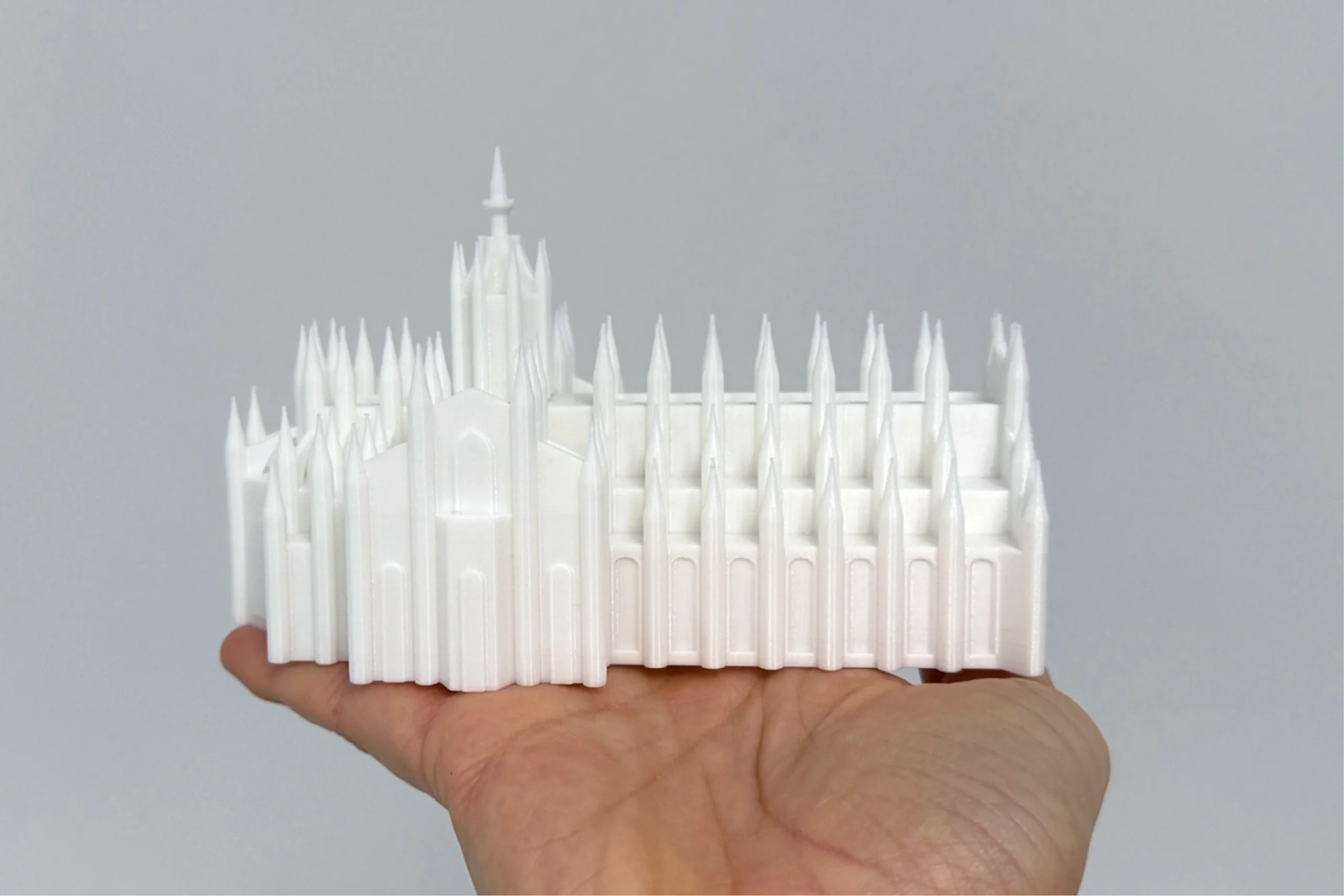

Replique solves these challenges with a decentralized manufacturing model. The platform connects companies to a global network of certified partners. This approach enables on-demand production. Consequently, companies need less warehouse space and can minimize inventory costs. Furthermore, it allows faster adaptation to market needs and reduces risks associated with overproduction.

Key Benefits with Replique

1. All from one source

We take care of supplier selection and handle the entire order along with the quality assurance process. Our platform connects with a broad supplier base and provides access to engineering services, digital warehousing, manufacturing and delivery.

2. Industrial grade quality

We work with certified partners. This is being done to ensure that every component meets the highest quality standards. We ourselves are certified according to ISO 9001 and 27001.

3. Personal Support

Our team guides you through every step from initial request to final order. So that companies can focus on what they do best while still benefiting from economies of scale.

Alstom’s Collaboration with Replique

A great example of how Replique’s digital manufacturing platform adds value is our collaboration with Alstom which became the first company in the railway industry to implement a certified serial production part using additive manufacturing. Through our on-demand production and digital warehousing services, Alstom shortened lead times and ensured industrial-grade quality across its supply chain.

Embrace the Future of Micromobility

By working together with just a single digital manufacturing platform, companies can simplify their sourcing strategy and produce parts on demand with no minimum order quantities. These platforms empowers such companies to thrive in a competitive market.

Discover how Replique’s digital manufacturing platform can transform your operations. Contact us today to learn more about how we can help you achieve efficient and flexible production.