Spare parts and emergency parts on demand

A reliable spare parts supply is essential for a profitable after-sales business.

With Replique, you optimize part availability – on demand, flexible, and without storage costs.

Long-tail parts: Reduce storage costs

- High warehousing costs for rarely used parts

- Missing availability of long-tail items

- Digital part management instead of physical inventory

- On-demand production – fast and flexible

Urgent parts: Handle unexpected needs

- Downtime due to missing components

- Long lead times in emergencies

- Manufacturing via flexible partner network

- Fast delivery to keep production running

The solution to your challenge

No part design available anymore? We can help!

Design support

Reverse Engineering

Process adaptation

Part optimization

Why produce spare parts and urgent needs on demand?

High availability through decentralized production

Replique manages your spare parts supply via a global network of qualified manufacturing partners.

This allows spare and SOS parts to be produced as needed and at short notice.

High availability through decentralized production

Digital storage replaces physical stock. Instead of warehousing thousands of parts, we store them digitally in our platform. Always accessible, no minimum order quantities.

Strong customer retention with “eternal spare parts”

Replique allows you to offer spare part availability well beyond the lifecycle of your machines or systems – a compelling sales argument for high-value capital goods.

Use cases

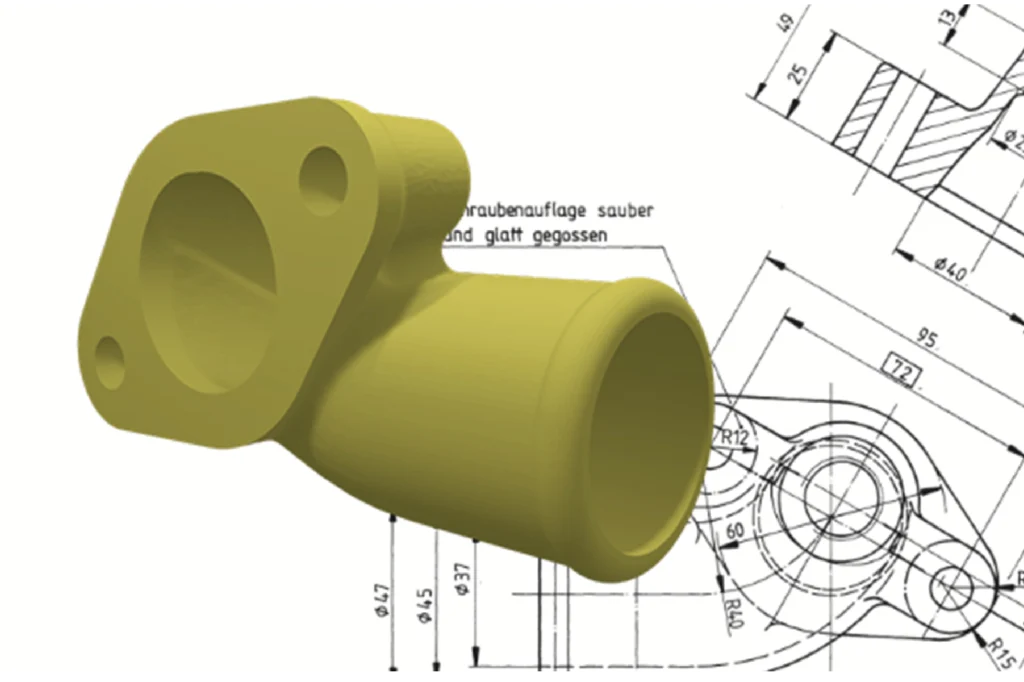

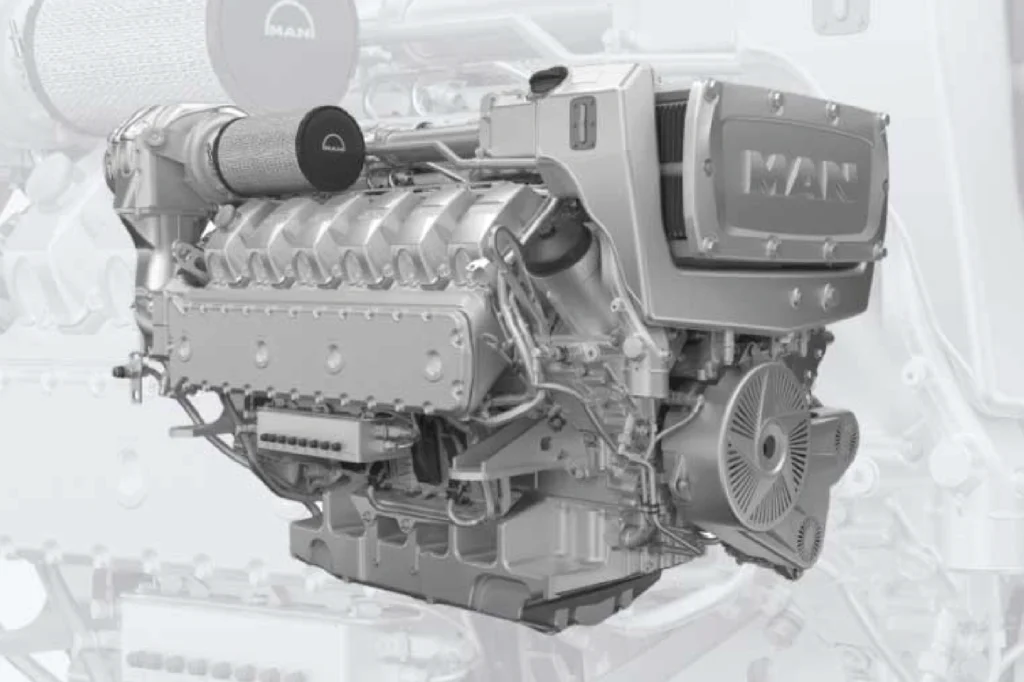

Securing spare part supply for MAN Truck & Bus

Background

Spare parts for the bronze cooling water manifold of a MAN diesel marine engine were no longer available.

The casting mold was missing. The part had to meet particularly high requirements in terms of corrosion resistance and mechanical load capacity.

Solution

The parts were produced via 3D printing and were available within 6 weeks.

Replique selected a material that is technically equivalent to the original (m4p™ Brz10).

This eliminated the need for a casting mold, while meeting the high standards for corrosion protection and durability.

Part qualification, material & technology selection

Production of the cooling water manifolds via 3D printing

Ready for use in the marine engine just 6 weeks after the initial request

Train spare parts on-demand with railauction.plus

Background

Replique cooperates with railauction.plus, the online marketplace for rail vehicles of DB Fahrzeuginstandhaltung GmbH, the maintenance division of Deutsche Bahn. With on-demand 3D printing, we ensure that companies receive spare parts exactly when they need them. Without minimum order quantities, storage costs and with minimal downtimes. Need a part quickly? Simply order via our quoting module.

Just 3 steps to your on-demand spare part

Upload data

Upload your CAD file, technical drawing, or sketch and select technology and material.

Review quote

We check feasibility, suggest optimizations if needed, and send you a tailored offer.

Receive spare parts

We produce the parts via our partner network and handle logistics.