Formnext 2025

Meet your all-in-one 3D printing partner

18 – 21.11.2025

Frankfurt | Hall 12.1, Booth B95

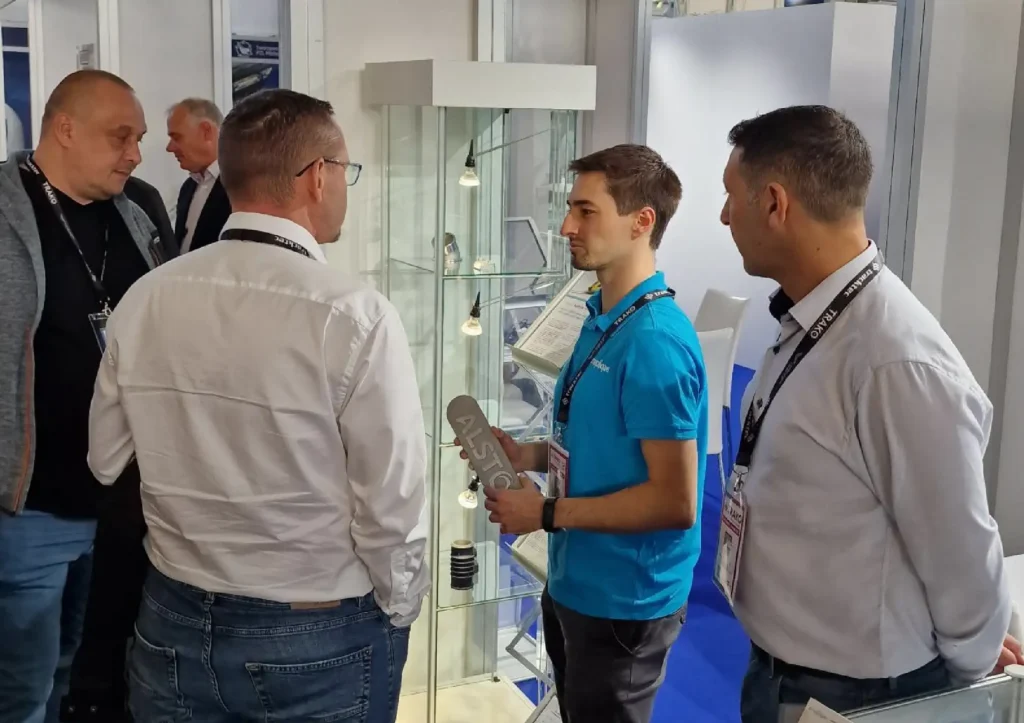

100+ customers already rely on Replique for their part sourcing

Meet us at Formnext 2025

There are so many 3D printing providers out there. But managing them all? Not exactly simple.

That’s where Replique comes in. Our platform allows reliable production across a wide range of materials and technologies via a single partner.

At Formnext, we’ll showcase how companies like Alstom, MAN, and Roche use Replique to make part production easier and faster.

📍 Find us in Hall 12.1, Booth B95, and see how it works.

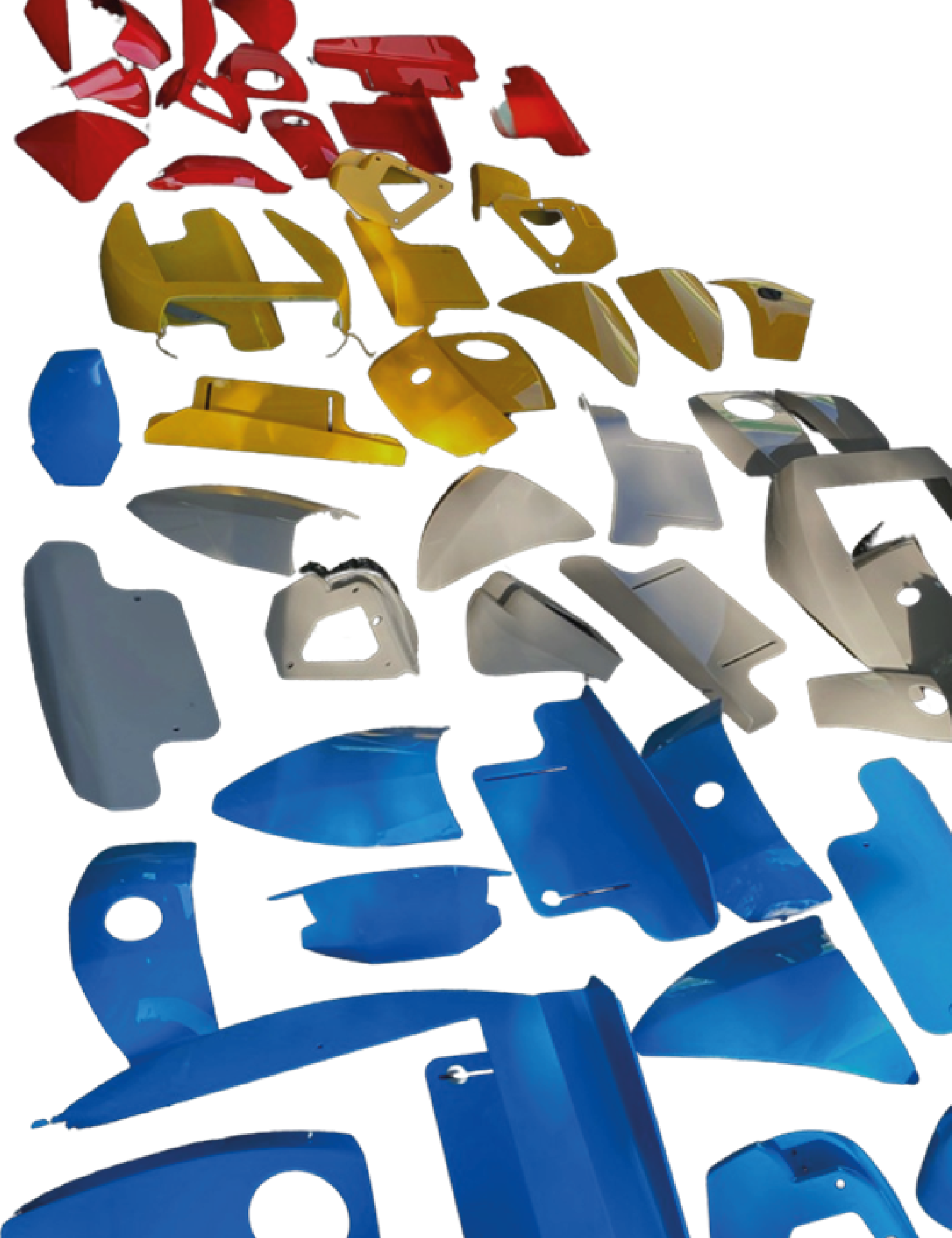

Discover our wide range of technology options!

Fused Deposition Modeling (FDM)

Stereolithography (SLA)

Selective Laser Sintering (SLS)

Selective Laser Melting (DSLM/SLM)

Multi Jet Fusion (MJF)

Binder Jetting

(BJ)

In all common 3D printing materials

3D printing polymers

Versatile for functional prototypes, serial parts, and spare parts.

Key properties (depending on material):

- Flame-retardant (e.g. certified to EN 45545-2)

- Flexible

- UV and weather resistant

- Chemical resistant

- Bio-based / sustainable

Common materials:

PA12, PA11, TPU, PP, ABS, PC, PETG

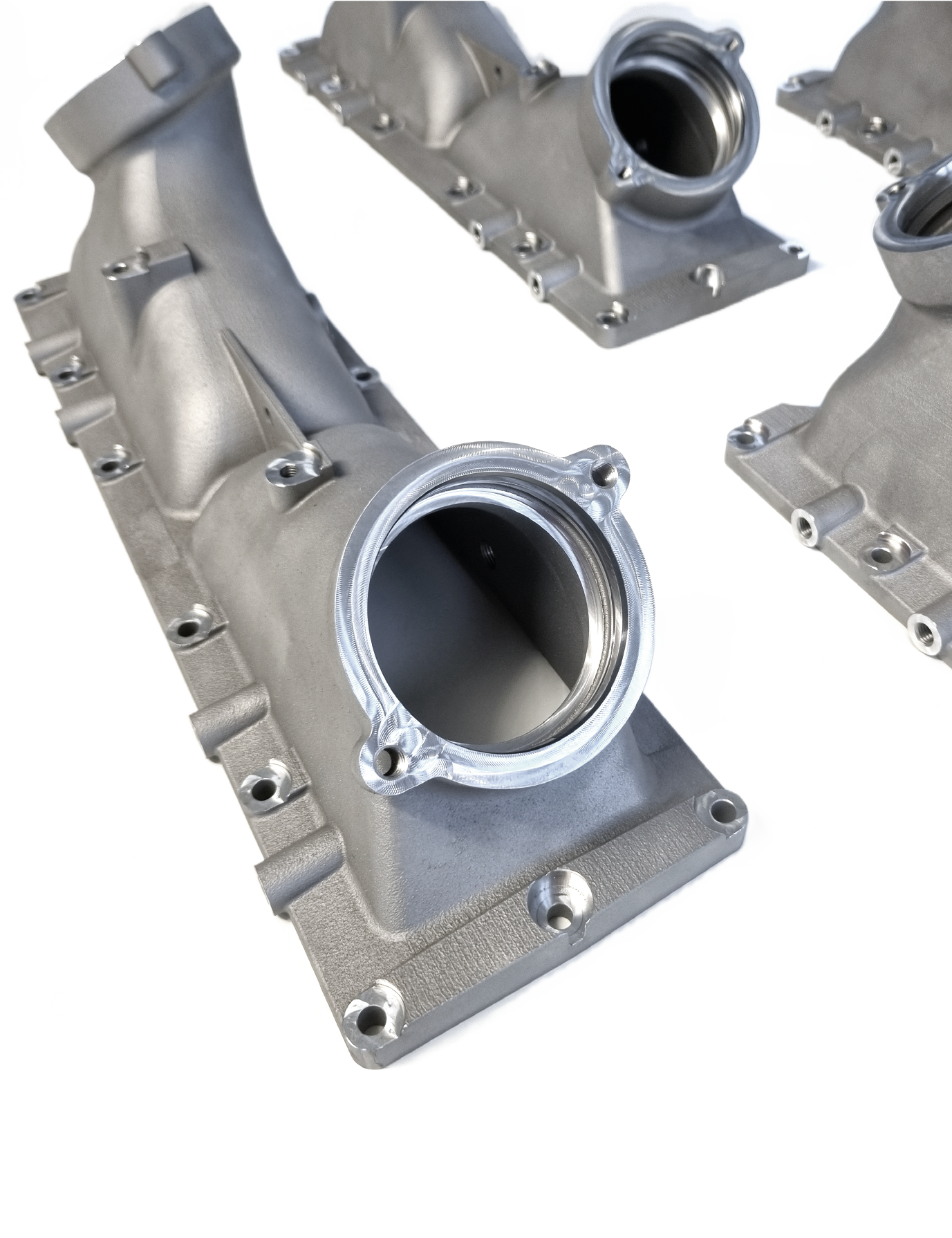

3D printing metals

Ideal for high-performance parts in mechanical and plant engineering

Properties (depending on material):

- High mechanical strength

- High temperature resistance

- Well suited for machining and heat treatment

- Can be certified for industry-specific applications (e.g. railway, aerospace)

Typical materials:

Aluminum (AlSi10Mg), stainless steel (316L, 17-4PH), titanium (Ti64), Inconel 625

3D printing resins

Perfect for detailed prototypes, functional parts, and specialized applications like microfluidics or dental technology

Properties (depending on material):

- High level of detail and smooth surfaces

- Printable in transparent or flexible materials

- Resistant to temperature and chemicals

- Biocompatible (e.g. for dental or medical applications)

Typical materials:

Standard resins, flexible resins, high-temperature resins, biocompatible resins, transparent resins

Other 3D printing materials

In addition to plastics, metals, and resins, we also offer 3D printing with alternative materials.

These include, among others:

- Technical ceramics – ideal for parts that must withstand extreme temperatures, offer high wear resistance, or require electrical insulation.

Composite materials, such as carbon or glass fiber-reinforced materials – particularly suitable for parts requiring high stiffness and strength while remaining lightweight. Perfect for specialized applications in aerospace or motorsport.