As we entered 2025, the world of 3D printing continues to evolve, not as a niche innovation but as a fundament instrument shaping industries. Let’s take a closer look at some of the major 3D printing trends in 2025.

1. 3D Printing Evolving into a Standard Technology

We are no longer approaching 3D printing as a stand-alone technology. It is becoming more and more viewed as “just another tool in the toolbox” in 2025. Businesses no longer ask, “Can we use 3D printing for this?” when addressing issues. Rather, they determine the best way to overcome their problems, and sometimes, 3D printing is (part of) that solution. Although it might not in every case be the best option, its strength lies in specific areas such as on-demand and decentral manufacturing, lightweight designs, and customization. For many applications, it has become synonymous with agility and innovation.

To follow up with that development, standardized procedures and verified materials will be key to ensure consistent quality and safety as 3D printing expands into critical sectors like healthcare and aerospace.

2. Increasing Price Pressure by Asian suppliers

The Asian suppliers remain at the forefront in driving down costs in 3D printing. With large-scale production capabilities and investments in innovation, countries like China are dominating the global supply chain for affordable printers, materials, and components.

For Europe, this presents both a challenge and an opportunity. In order to remain competitive, European businesses need to prioritize value over pricing. This can include providing localized production, guaranteeing sustainable practices, and delivering superior quality. This shift will likely boost innovation in Europe’s additive manufacturing sector.

3. Consolidation in the 3D Printing Industry

Consolidation is a key effect in the 3D printing sector in 2025. As of 2024, a number of additive manufacturing businesses have either merged with larger companies or left the industry as a result of financial difficulties. This tendency is likely to continue, resulting in a more streamlined and concentrated market with only the most inventive and powerful firms left. While this reduces the variety of options, e.g. for certain materials, it also enhances the stability and reliability of the market. Leading manufacturers are now focusing on refining their offerings and expanding their product portfolios to meet growing demands. The increased concentration of suppliers also creates opportunities for collaboration.

4. AI-Driven Design and Process Optimization

Artificial intelligence is influencing every stage of 3D printing, from design to production, and thus becomes a key trend in 2025. AI-powered tools will increasingly enable fast prototyping and design iterations but also optimize manufacturing processes like automated quoting, material selection, and error detection.

By integrating AI into workflows, businesses can reduce costs, minimize material waste (e.g. by predicting potential misprints early on), and overall create parts that are more efficient, durable, and cost-effective.

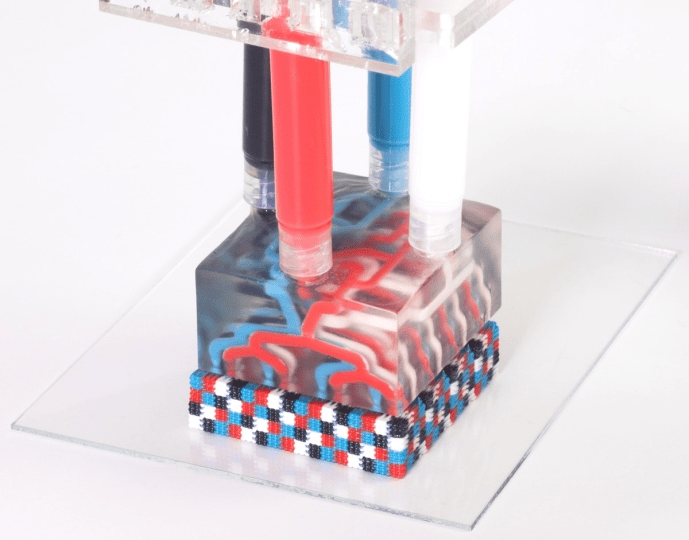

5. Advanced Materials and Multi-Material Printing

Material innovation remains a key driver of growth in 3D printing. By 2025, we see significant advancements in materials like carbon-fiber composites, high-performance polymers, and metal alloys, all of which provide increased strength, durability, and functionality.

Another trend that is gaining popularity is multi-material 3D printing, which opens up interesting new possibilities by producing complicated parts with different properties, such as soft-touch surfaces alongside rigid supports.

6. Scaling Up: Large-Format 3D Printing

Another 3D printing trend in 2025 is large-format 3D printing, breaking size barriers and enabling the production of massive components for industries like construction, aerospace, and energy. With innovations in printer technology and materials, creating everything from building walls to wind turbine blades is becoming more efficient and accessible. This trend is driving scalability and new applications across various sectors.

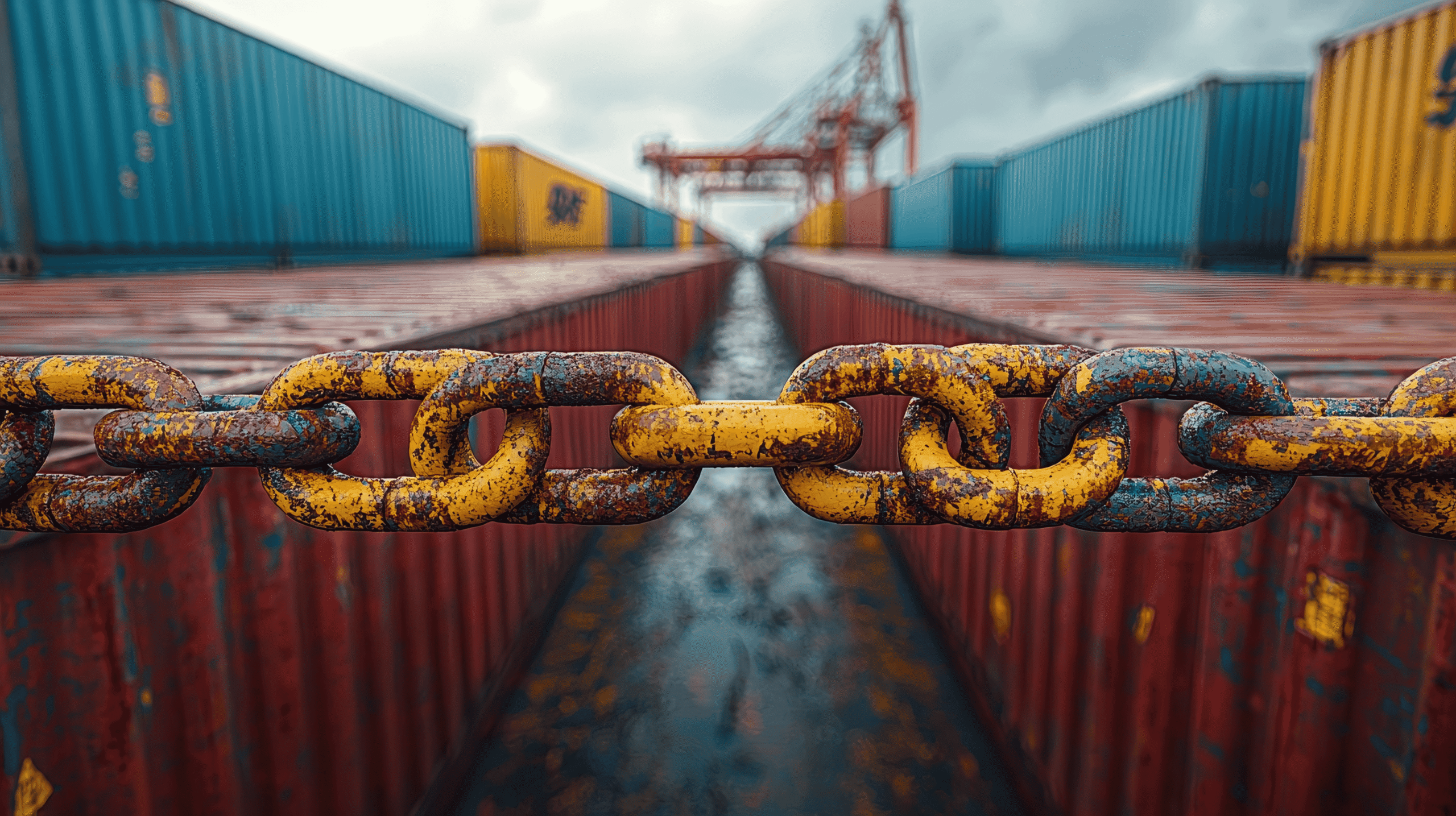

7. Owning machines is not the solution

In 2025 companies increasingly recognize the value of distributed manufacturing for building resilient and scalable supply chains, especially for specialized and longtail parts. Many of our customers are shifting from in-house production to distributed manufacturing to meet growing demands efficiently. While 3D printing has led the way in this shift, other technologies are also following.

Access to localized production networks expands allowing companies to produce parts closer to demand. This reduces transportation costs, shortens lead times, and enhances flexibility. Cloud-based platforms further streamline the process by enabling easy sharing of digital files and coordinating production globally. This further reduces the effort for companies in finding the right supplier, as they gain access to an entire procurement network through a single platform. By this, cloud platforms solve the challenge of 3D printing technology complexity, by not being pushed into owning machines.

8. 3D Printing’s Next Big Leaps?

In 2025, the 3D printing industry focuses on innovations that drive industrial-grade applications. Businesses such as Chromatic 3D Materials, for instance, are leading the way in the utilization of chemical reactions in 3D printing, making it possible to produce industrial-strength elastomeric parts suitable for various applications.

Tritone’s MoldJet technology offers an innovative powder-free additive manufacturing process that makes it possible to produce metal and ceramic parts in large quantities quickly and efficiently.

The STEP technique from Evolve Additive produces products with precise details and strict tolerances, rivaling injection molding in speed and precision.

Additionally, large companies such as EOS with its LaserProFusion technology, for example, aim to reduce production time and enhance efficiency, potentially replacing injection molding in complex parts and small-series production.

These are only a few illustrations of the developments in the field of 3D printing. However, as with any emerging technology, their market impact will depend on real-world performance and adoption rates. The industry will closely monitor how these advancements fulfill their promises and influence market dynamics in the coming years.

Conclusion: Embracing 3D Printing as the New Normal

As 3D printing steadily marches toward industrialization, 2025 marks the year it fully integrates into the broader manufacturing ecosystem. It is one of many tools solving modern challenges, sometimes the best choice, sometimes not.

This development demonstrates the technology’s adaptability and its potential to drive significant change in a variety of sectors. Whether through AI, advanced materials and printers or industry-specific innovation, 3D printing remains a key player in shaping the future of manufacturing.