Your project in good hands.

From the initial idea to part optimization and final production readiness – our engineering team is here to help make your project a success.

All services from a single source

Do these challenges sound familiar?

- No 3D model available

- Uncertainty about material or technology selection

- Need to optimize part design

Our engineering team supports you from the first idea to the finished part to ensure your project becomes a success.

Overview of our engineering services

Reverse Engineering

No 3D CAD model? That’s often the case with older spare parts. Based on a drawing or even just a physical sample, we create an accurate 3D model for you.

Feasibility Studies (PoC)

We support you with feasibility studies to find the best solution for your specific use case – technology-agnostic and in line with the latest industry standards.

Design Optimization

We optimize part geometry to reduce weight and material usage – without compromising functionality. A key focus: Design for Additive Manufacturing (DfAM).

Part Design & CAD

We support you in developing new components – from the initial idea to a complete 3D design, tailored to your preferred manufacturing method.

Technology Consulting

We advise you on selecting the most suitable materials and production technologies – based on your specific part requirements.

Simulation & Validation

We use standard methods (e.g., FEM) to simulate how parts perform under stress – ensuring durable, high-performance components that meet your requirements.

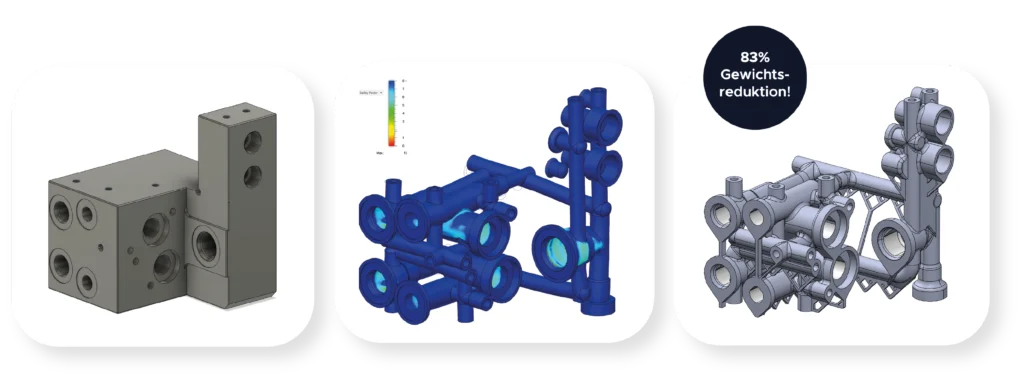

From CNC to optimized additive manufacturing with DfAM

Originally manufactured from a solid steel block, this hydraulic block was optimized by us for production via 3D printing.

Using FEM-based design, the weight was reduced by 83% – while maintaining the same pressure resistance.

The material used was stainless steel 316L, matching the original material S355J2+N.

Want to explore what’s technically possible?

We’ll be happy to advise you to find the best solution for your part.