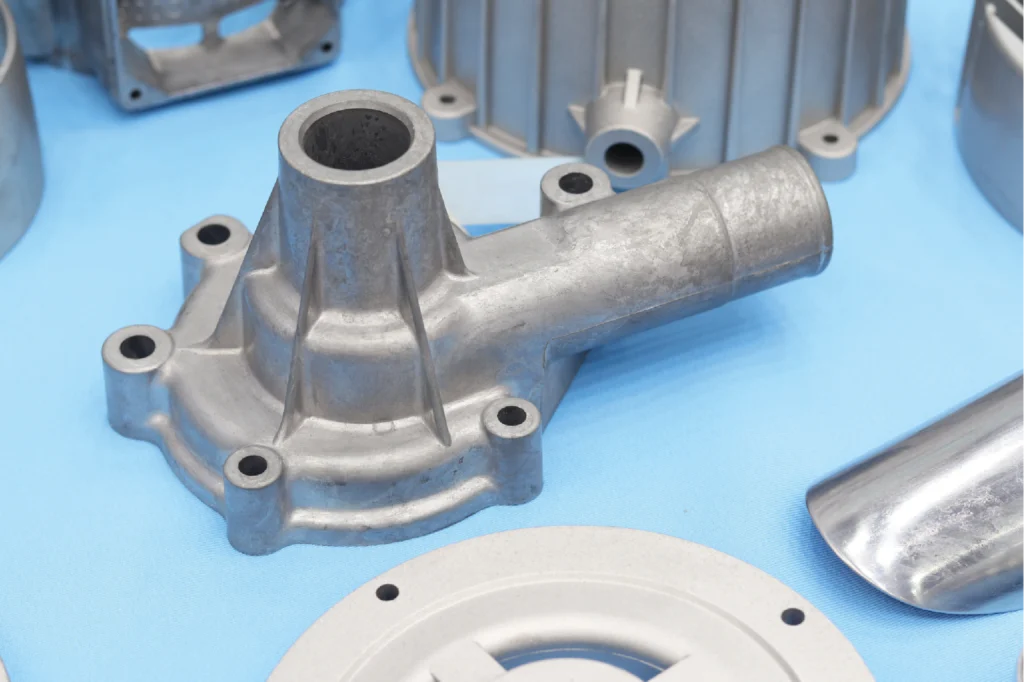

Cast parts: Complex geometries and a wide range of materials

Cast parts are the right choice when complex shapes, high strength, and specific material properties are required. Replique delivers your casting needs – digitally, efficiently, and reliably.

Why source cast parts with Replique?

Sourcing cast parts usually involves a lengthy supplier search and significant coordination effort.

With Replique, you receive a prompt all-inclusive quote – covering pattern creation, casting, machining, and quality assurance – all from a single source.

Casting at a glance

Common materials

- Cast iron (GG, GGG)

- Steel and stainless steel alloys

- Non-ferrous alloys (e.g. aluminum and copper-based)

- Others upon request

Popular casting processes

- Sand casting (low dimensional accuracy, high design flexibility)

- Investment casting (high dimensional accuracy, fine details)

- Die casting (very high precision, fast production speeds)

- Permanent mold casting (medium precision, good repeatability)

- Centrifugal casting (very accurate, ideal for rotationally symmetrical parts)

Suitable for

- Parts with complex geometries

- Components requiring high load resistance

- Parts with specific material requirements

To ensure your cast parts are ready to use...

…we offer a range of surface finishing and post-processing options.

So nutzt XY unsere Dienstleistungen für Gussteile

Problem

Bronze-Kühlwasserkrümmer eines Marinemotors fehlen, aus Bronze gefertigt, für hohe Anforderungen.

Lösung

Teile produziert mittels 3D-Druck, verfügbar innerhalb von 6 Wochen. Material: Bronze wie bei Original

Qualifizierung der Bauteile, Material- und Technologieauwahl

Produktion der Kühlwasserkrümmer mittels 3D-Druck

Einsatzfertig für den Marinemotor in nur 6 Wochen nach Anfrage

Replique benefits at a glance

Everything from one source

We take care of supplier selection and auditing, and handle the entire order process for you.

Industrial-grade quality

We work exclusively with certified partners and guarantee top quality standards.

Personal support

Our team guides you through every step – from your initial request to final delivery.