3D printing: Fast solutions with versatile applications

3D printing is the ideal choice for small and medium batch sizes – especially when speed matters and there’s no time for molds or tooling. With Replique, you get access to all major 3D printing technologies, including plastics, metals, and more.

Why 3D printing with Replique?

There are plenty of 3D printing providers out there. But we don’t just print your parts – we work closely with you to find the best solution for your complex requirements.

- Prototypes, one-offs, and series production

- Repeatable tolerances and reliable processes

- Support with Design for Additive Manufacturing (DfAM)

- Industry-specific standards like EN 45545, ISO 10993, FDA, and more

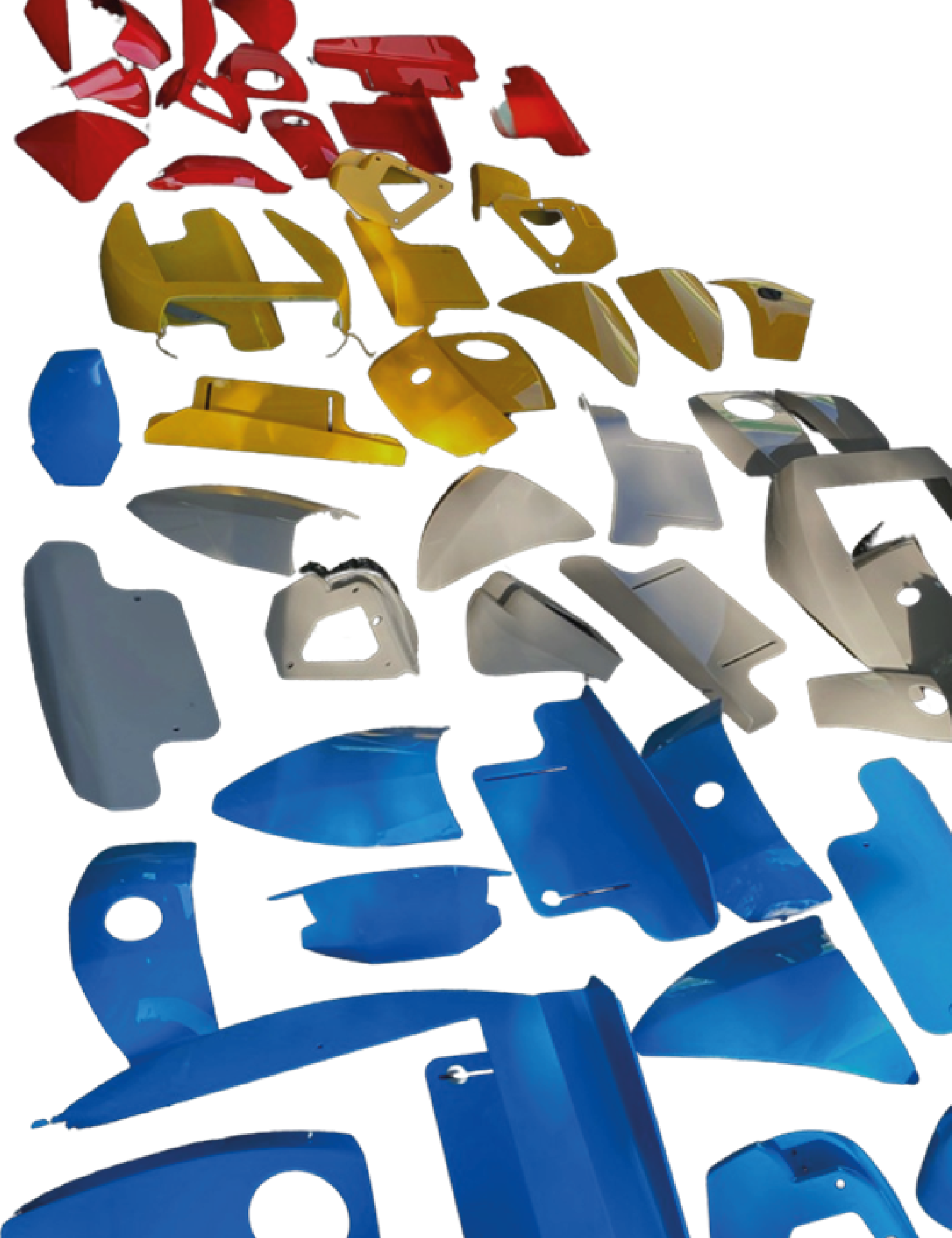

3D printing polymers

Versatile for functional prototypes, serial parts, and spare parts.

Key properties (depending on material):

- Flame-retardant (e.g. certified to EN 45545-2)

- Flexible

- UV and weather resistant

- Chemical resistant

- Bio-based / sustainable

Common materials:

PA12, PA11, TPU, PP, ABS, PC, PETG

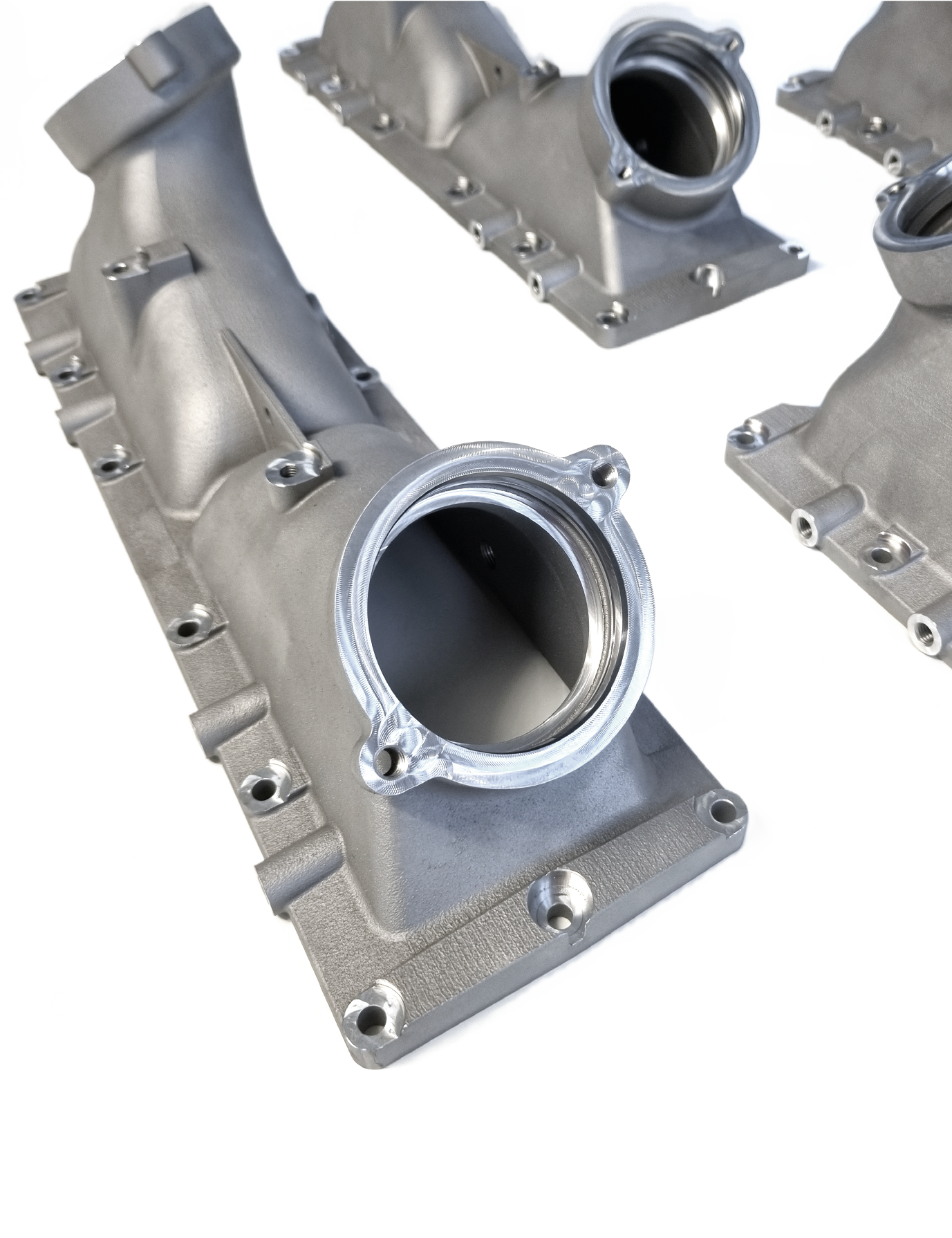

3D printing metals

Ideal for high-performance parts in mechanical and plant engineering

Properties (depending on material):

- High mechanical strength

- High temperature resistance

- Well suited for machining and heat treatment

- Can be certified for industry-specific applications (e.g. railway, aerospace)

Typical materials:

Aluminum (AlSi10Mg), stainless steel (316L, 17-4PH), titanium (Ti64), Inconel 625

3D printing resins

Perfect for detailed prototypes, functional parts, and specialized applications like microfluidics or dental technology

Properties (depending on material):

- High level of detail and smooth surfaces

- Printable in transparent or flexible materials

- Resistant to temperature and chemicals

- Biocompatible (e.g. for dental or medical applications)

Typical materials:

Standard resins, flexible resins, high-temperature resins, biocompatible resins, transparent resins

Other 3D printing materials

In addition to plastics, metals, and resins, we also offer 3D printing with alternative materials.

These include, among others:

- Technical ceramics – ideal for parts that must withstand extreme temperatures, offer high wear resistance, or require electrical insulation.

Composite materials, such as carbon or glass fiber-reinforced materials – particularly suitable for parts requiring high stiffness and strength while remaining lightweight. Perfect for specialized applications in aerospace or motorsport.

A broad range of materials for every application

Looking for the right 3D printing material?

With free access to our Material Hub, you can quickly find the best match for your application.

Fused Deposition Modeling (FDM)

Extruded filament is deposited layer by layer.

Use case: Cost-efficient, durable parts in a wide range of materials.

Stereolithography (SLA)

Liquid resin is cured with UV light.

Use case: High-resolution parts with smooth surfaces.

Selective Laser Sintering (SLS)

Powder (usually plastic) is fused with a laser.

Use case: Robust, complex parts with isotropic properties.

Selective Laser Melting (DSLM/SLM)

Metal powder is fully melted with a laser.

Use case: Strong metal components with complex geometries.

Multi Jet Fusion (MJF)

Powder is selectively treated with a fusing agent and then fused using infrared light.

Use case: High-precision parts with fine details and smooth surface quality, fast production.

Binder Jetting

(BJ)

Powder is bound layer by layer using a liquid binder and later sintered.

Use case: Fast and cost-efficient production of even large parts.

The most common 3D printing technologies

To make sure your parts are ready to use from the start…

…we offer a range of finishing and post-processing options.

How Alstom uses Replique’s 3D printing service

Challenge

A custom request for a doorstopper. In traditional manufacturing (e.g. casting), small quantities typically result in high costs and long lead times.

Solution

Thanks to Replique’s 3D printing platform, Alstom was able to produce and qualify the part within just 1.5 months – as the first visible metal 3D printed part installed on a train.

Design iterations to finalize the prototype

3D printing with Ultrafuse® 316L, followed by debinding and sintering

Series qualification and delivery in 6 weeks – ready for use in the train

Replique benefits at a glance

Everything from one source

We take care of supplier selection and auditing, and handle the entire order process for you.

Industrial-grade quality

We work exclusively with certified partners and guarantee top quality standards.

Personal support

Our team guides you through every step – from your initial request to final delivery.